For a component-based electronic access control system, power must be supplied to the controller, credential reader, sensor and electrified locking mechanism. For most applications, low voltage power and sensor wiring are run from the controller and power supply to the opening.

Depending upon the method used to control access, the locking mechanism can be installed at the jamb or the door. If the locking mechanism is located at the jamb, such as an electric strike, bolt or electromagnetic lock, cabling is run down within the wall to the credential reader, sensor and the locking mechanism.

If the locking mechanism is installed in the door, a power transfer mechanism must be installed to run power through the gap between the jamb rabbet and door edge. Electrified locks, trim and exit devices require a power transfer mechanism. A power transfer mechanism moves the power and sensor across the opening (gap) between the jamb and the door.

Different types of power transfer mechanisms and methods are used making the transfer. Prior to choosing a power transfer mechanism, you must know the power and sensor requirements and determine if the device can accommodate them. This includes the wire count and gauges required for the electrified lock, trim or exit device and the sensors/switch.

When installing electromechanical access control on a fire rated opening, make sure the power transfer mechanism is properly listed for a fire door opening. It should carry the fire rated mark, meeting the criterion of the opening.

Power transfer mechanisms come in three types: exposed, concealed and invisible. Each type has advantages and disadvantages depending upon the opening, location and the application.

Exposed Power Transfer

Exposed power transfers are the surface mounted door loops or armored door cords. They are visible when the door is open and closed. A door cord/loop is a small diameter flexible metal (armored) conduit with connectors (metal or plastic) at each end that are surface installed onto the jamb and the door face or directly into the exit device body. Depending upon the manufacturer and model, conduit diameter and length can vary. The larger the diameter, the greater the number and the smaller gauge wires that can be contained. Most door cords/loops do not come wired.

The disadvantage of surface mounted power transfer products is they are exposed. The advantage is they are inexpensive and relatively easy to install. For additional protection, door cords/loops can be installed high up on an aluminum-glass stile door or hollow metal door that does not containing blocking.

Concealed Power Transfer

Concealed power transfers provide a wiring path from the jamb rabbet into the door edge. They are tamper resistant when the door is closed. However, they are visible when the door is open as the faceplates, back-box or mounts and the conduit, flexible steel shields or telescoping tube becomes visible. Concealed power transfers are available in a variety of configurations including Electric Power Transfers, Concealed Door Loops and the PowerJump.

Electric Power Transfer

There are different designs of Electric Power Transfers (EPT), with some telescoping and flexible steel shield style models having a back-box for both the hinge side jamb rabbet and door edge. Some flexible steel shield style EPTs have a single back-box with a connector. Installing a back-box requires a radiused or a rectangular cutout.

EPTs are normally positioned between upper full mortise butt hinges at least six inches above the middle hinge. They are not designed to accommodate all types and sizes of butt hinges, continuous hinges and pivots.

For example, the maximum swing for doors equipped with Von Duprin Electric Power Transfer models EPT-2 and EPT-10 are:

- Butt Hinges (up to 5") – 180 degrees

- Butt Hinges (up to 5-1/2") – 130 degrees

- Butt Hinges (up to 6") – 110 degrees

- Offset Pivots (up to 3/4") – 180 degrees

Von Duprin EPT-2 and EPT-10 should not be used on doors equipped with swing clear hinges, center-hung pivots or offset pivots with greater than ¾" offset.

Concealed Door Loop

An alternative to the EPT is the Command Access Concealed Door Loop (CDL). The CDL requires a hollow door or stile and a hollow jamb. This ¼" inside diameter flexible armored conduit slides between two mounting rings. The ends of the conduit have rubber caps that limit the travel. The mounting rings can be installed into the hinge side jamb rabbet and the door edge, permitting the conduit to extend out as the door is opened and retract as the door is closed. The CDL can be installed through the door edge and the jamb face. It can also be installed through the two leafs of a butt hinge or full mortise continuous hinge. As an optional installation, one end of the conduit can be fixed at the door edge. The remaining portion will extend and retract into the jamb.

For storefront aluminum glass doors equipped with ¾" offset pivots, the Command Access Technologies CDL-EXT has a longer ¼" inside diameter flexible armored conduit. One end of the CDL-EXT armored conduit is fixed at the door edge. The remaining portion extends from and retracts into the aluminum jamb. The CDL-EXT supports up to 105-degree door swing on ¾" offset pivot equipped openings.

PowerJump

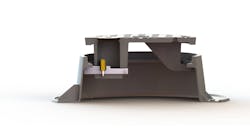

For a contactless power transfer only, Securitron offers the PowerJump Inductive Coupling Power Transfer (ICPT). The concealed Securitron PowerJump ICPT mechanism transmits field selectable 12VDC or 24VDC power (up to 6 watts) across the opening between the jamb rabbet and the door edge without any wires, pins or physical contact. The PowerJump transfers power across a gap of up to 3/16" from the Send Unit to the Receive Unit. Power is lost when the door is being opened. The faceplates of the PowerJump Sending and Receive Units are visible when the door is open.

The PowerJump ICPT is designed for Fail Secure electrified locking devices and other door mounted hardware requiring up to six watts (0.5 A@12VDC/0.25 A@24VDC). The Receive Unit can be installed on the door's latch edge, hinge edge or top edge, with the Send Unit in alignment within the jamb rabbet. Input power is 24VDC up to 500mA max. The PowerJump is UL10C fire-rated for 3 hours.

The disadvantage of EPT and the PowerJump is the time required to install these products. They cannot be installed into fire rated openings. The advantage of the EPT and the CDL is the number of wires and the amount of power that can be transferred between the jamb rabbet and the door edge. When ordering a concealed power transfer, make sure the number and wire gauge is compatible with the locking mechanism and any sensor or component.

Invisible Power Transfer

The third category is the invisible power transfer, meaning it does not appear to be a power transfer. An invisible power transfer is a standard door component such as a butt hinge, continuous hinge or pivot. Most electrified hinges or pivots look no different electrified. No wires are visible when the door is closed or open. Using an electrified full mortise butt hinge, continuous hinge, center hung top pivot, intermediate (side jamb) pivot, bottom pivot or pocket pivot provides vandal resistance by concealing sensor and low voltage wires between the jamb and the door.

Steel and stainless steel pin and barrel and aluminum geared continuous hinges are available electrically modified. Depending upon the manufacturer, the electrification can be built into the full length continuous hinge.

Continuous Hinge

A second option is modifying the continuous hinge, creating an access panel for the wiring between the jamb and door. There are two possible configurations. One is having the access panel manufactured into one leaf only. The second configuration has an access panel in each leaf. This way, if there is a wiring problem, having an access panel in each leaf can eliminate having to remove the hinge in order to make the repair.

The third option is to have a separate removable section for the power transfer, modifying the continuous hinge into three sections. The middle section contains the power transfer.

Continuous hinge power transfer configurations can vary by manufacturer and hinge material. When ordering a continuous hinge, make sure the number and wire gauge is compatible with the locking mechanism and any sensor or component. Power transfer aluminum geared continuous hinges are available as full surface and full mortise.

An advantage of a continuous hinge is the ability to adjust the door position vertically and horizontally. This ensures the door can properly fit into the opening. Continuous hinges can often solve the problems of settling and door warpage. The disadvantage of continuous hinges is they are more expensive than butt hinges.

Pivot

The second option of the invisible power transfer is the pivot. There are three types of pivots; offset, center hung and pocket pivot. Offset and center hung pivots are a hinging mechanism where the weight of the door is supported entirely by the floor-mounted bottom pivot spindle arm. A top pivot keeps the door vertical within the opening. For doors 60 to 90 inches tall, a required intermediate pivot provides alignment and additional support. The pocket pivots are specially designed for pocket doors. These cross-corridor doors sit in a pocket in the wall. The pocket pivots swing these doors 90 degrees to close.

Power transfer pivots are available as center hung top pivot, center hung bottom pivot, intermediate (side jamb) pivot and pocket pivot. Intermediate pivots are brass and top, bottom and pocket pivots are steel. Wire options can vary by manufacturer. The electrified bottom pivot is available from Rixson as a special order. The part number is EH117-3/4.

Center hung top and bottom pivots run the wiring through the spindle shaft. The intermediate pivot configuration is similar to a two knuckle hinge, having a hollow insert that interconnects the knuckles. The wiring runs through one leaf, the hollow insert and out the other leaf. Intermediate pivots are manufactured not to be disassembled. Pocket pivot are wired through the center of the jamb portion and out the center of the door portion.

Butt Hinge

The third option is the butt hinge, the most common hinge used on swinging doors. Hinge manufacturers and aftermarket electrification companies modify standard or heavy duty ball bearing, full mortise butt hinges. In fact, if you know the manufacturer and the specifics of the door’s butt hinge, it can be electrified. The 4.5" and 5" butt hinges are most common commercial sizes. Most electrified butt hinges are manufactured from steel or stainless steel. To electrify a butt hinge, the leafs are edge drilled into the knuckle and the back face is drilled for the exits to create the wire paths. Since the hinges are full mortise, the edge holes are not visible once installed into the jamb rabbet.

Electrified butt hinges have two modified (shortened) non-removable pins installed at the top and bottom of the knuckles, providing a center channel for the wires to transfer from one leaf to the other. A roll pin or setscrew is installed through a knuckle and into each pin. The non-removable pin retention method is not visible when the door is closed, thwarting pin removal. When the door is open, non-removal pin holes in the butt hinge knuckle identify it as an electrified butt hinge.

Important: Electrified hinges no longer meets manufacturer load bearing specifications. For this reason, the electrified hinge should always be positioned as the center or one of the center hinges.

Butt hinges can accommodate from two up to 10 or 12 wires. The number of wires can determine the gauge. Usually two wires are 18 or 20 gauge to accommodate the locking mechanism power demand. The remaining wires can be 24 to 28 gauge, to accommodate sensors on door credential readers and request to exit bars.

In addition to providing sensor and low voltage electricity, butt hinges can be equipped with a concealed switching mechanism that monitors the position of the door. Electrified Monitoring Hinges can have two separate cables extending from the jamb leaf, one for transfer and the other for a door position switching mechanism. The door position switching mechanism will usually have three small gauge wires, providing the option of Normally Open, Normally Closed and the Common.

When butt hinges are electrically modified, an opening must be drilled into the door edge and the jamb rabbet to run the wiring through the electrified hinge to the device. The location of the wire access holes can vary by manufacturer and model of butt hinge as well as the jamb and door leaf. One common wire access hole location is centrally located along the horizontal centerline of the butt hinge (between the second and third screw hole). Some wire access holes are up or down in the middle or near the edge. Since some electrified butt hinges are handed, non-centered wiring locations must be determined prior to drilling the raceway or access holes.

A less common option for invisible power transfer is the swing clear butt hinge. Swing clear full mortise hinges are expanded offset hinges that widen the access through a doorway by swinging the door completely clear of the opening. Each leaf of the swing clear hinge has the hinge knuckle (barrel) offset to a location along the face of the hinge jamb. This offset removes the door edge and the hinge knuckle from the opening, providing a clear full width opening at approximately 95 degrees, enabling the full width of the opening to meet code and ADA requirements. Important: Swing clear hinges require additional space between the door jam and adjoining wall for the hinges to have sufficient space to swing.

There are two basic method of creating electrified swing clear hinges. The first method is drilling the wire holes when the hinge leaves are flat, then bending the leafs. The second method is bending (offsetting) the leafs and then machining the wire paths. The flat method requires straight holes through the thickness of the leaves into the knuckle. There is no visible evidence of the modification as the wires are in the hinges when bent. The second or offset method is to bend the leafs, then drill and machine the openings for the wires. This method creates visible "tracks," which are filled in after the wires are installed. However, this modification can usually be seen.

PBB Electrified Hinges

For electrified standard and heavy weight full mortise 4.5" and 5.0" ball bearing swing clear hinges, PBB, Inc. manufactures electrified swing clear full mortise butt hinges without having visible tracks, by drilling the wire holes through the leafs and installing the wiring before making the offset. Wire options for the PBB swing clear hinges range from 2-20 gauge wires to 8-28 gauge wires. There can be an 8-10 week lead time for electrified swing clear butt hinges.

Wiring is provided for the invisible power transfer including the hinges and pivots. When ordering an invisible power transfer, make sure the number and wire gauge is compatible with the locking mechanism and any sensor or component. Most of these products cannot be rewired.

Before ordering pre-wired power transfers, determine if the locking mechanism has a four-foot lead, which will extend from the locking mechanism through the door out to a center mounted electrified hinge, intermediate pivot or door cord/loop. If the locking mechanism has a short lead, consider ordering the power transfer with a four-foot lead. This way, there is just one connection between the power transfer and locking mechanism.

If the power transfer is a center hung top or bottom pivot, ordering the locking mechanism and the pivot with a four-foot lead on each will eliminate having to make an additional connection.

Note: Some power transfer manufacturers offer custom connectors for their locking mechanisms and power transfers. Using connectors can make the installation more secure and easier if servicing is required.

Power transfer mechanisms bring power from the jamb to the door. As the article describes, there are many choices for your customers. Always choose the correct power transfer mechanism for the application, location and budget.

Important: Before purchasing or installing a component based electronic access control system onto a fire rated opening, contact your local Authority Having Jurisdiction.

For More Information

For more information on the companies discussed in this article, contact your local locksmith distributor or the following manufacturers:

- Command Access Technologies: www.CommandAccess.com

- PBB Hinges: www.pbbinc.com

- Rixson: www.rixson.com

- Securitron: www.securitron.com

- Von Duprin: http://us.allegion.com/brands/von_duprin/Pages/default.aspx