From 2000 to 2010, the number of Americans aged 65 or older plus increased to more than 40 million, up more than 15 percent. The ability to live an autonomous life is dependent upon the ability to get around. This includes getting into and out of businesses, doctor's offices and even senior living situations.

Even with eight-pound opening force requirements for non-fire rated exterior doors, a senior, disabled person or child can have difficulty safely navigating an opening.

Low energy power door operators provide access and egress solutions for people who have difficulties opening a door. Unlike high energy door operators that require additional safety components, low energy operators can just be equipped with activation devices. Some low energy door operators offer a standard 120VAC plug as an option to simplify installation.

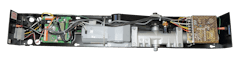

The Norton 6000 Series Low Energy Power Operator is designed for high traffic applications. The operator conforms to ANSI/UL standard 325 for Automatic Closing Doors and UL10C Position Pressure Fire Test for Door Assemblies. The door operator meets or exceeds ANSI A156.19 Power Assist and Low Energy Power Operated Doors and ANSI 117.1 Accessibility and Usability for Physically Handicapped People.

Basic features of the fire rated Norton 6000 Series include Push & Go, 1.3Amp onboard 24VDC power supply, obstruction detection, motor startup delay adjustment, relay and alarm output and presence detector input. The Norton 6000 Series can accommodate door widths up to 48 inches and doors weighing up to 250 pounds.

Two significant upgrades are incorporated into the Norton 6000 Series Low Energy Power Operator. First, the motor and closer body are mounted onto a bolt-on sub-assembly to simplify installation. Second, programming is accomplished using a joystick for the controller interface. To scroll through the menu, push the joystick up or down. To change a setting, push the joystick to the left to decrease the value or to the right to increase the value. When finished, to save the changes, scroll down to save values and press in on the joystick. All settings can be viewed on the built-in LCD screen.

The heavy components of any power door operator, the door closer and motor, can be removed from the mounting plate prior to installation. This enables one-man installation of the door operator mounting plate. Once installed, the motor/closer sub-assembly can mounted and secured.

The Norton 6000 Series operator is a combined motor driven door opener with a size one to six adjustable Norton 7500 Series door closer. When an activation switch is activated, the door swings open and remains open for the 0 to 30-second hold open time. When the hold-open times out, the door closes under pressure exerted by the door closer. This operator can be factory ordered with an infinite hold open.

If the door contacts an obstruction at any time during the opening or closing cycle, the door will reverse direction, either opening or closing. If the door contacts the obstruction a second time, the door remains against the obstruction until it is removed. Should power be lost, the 6000 Series operates as a mechanical surface-mount door closer closing the door.

Norton has equipped the 6000 Series with a 1.3Amp power supply to provide sufficient on-board power for most solenoid or motor driven door locking hardware. This eliminates the need for a separate power supply.

Installation

I was invited to the installation of a Norton 6000 Series Low Power Door Operator onto the interior (push) side of an aluminum glass medium stile door in a curtain wall. The door is the left leaf of a double door opening. The doors are equipped with concealed vertical rod exit devices. The left door exit device will be dogged during the hours the operator will be powered.

The Norton 6060RF was ordered with two 6" square, surface mount activating door switches. These stainless steel switch plates activate radio frequency (RF) transmitters operating at 433 MHz. An RF Receiver operating at 433MHz was pre-installed onto the door operator.

The facility where the Norton low power operator was installed has an exterior double door entry into the dining room. The entry is contained within a curtain style wall built with extruded aluminum members. The wall is infilled with glass and gives natural light the ability to penetrate into the building.

Important: Because this wall is not structural, a ¼" thick aluminum plate was constructed to mount on the aluminum framework, providing structural support and a solid mounting surface for the door operator. The bottom portion of the plate was secured to the edge of the header, and the top portion of the plate had a 90-degree bend creating a ½" "L" that reinforces the plate. The plate spans between the vertical members on each edge of the double doors.

The double aluminum glass narrow stile doors are mounted into the jamb with an overhead, concealed door closer and a center hung bottom pivot. For this installation, the door closer was removed and disabled by draining the fluid and removing the springs. It was reinstalled to function as the top pivot.

The aluminum plate was temporarily mounted onto the aluminum framework and measurements were made to locate the door operator. Holes were drilled and threaded where applicable. The plate was located onto the wall again and holes were located for mounting the plate onto the aluminum framework. Holes were drilled into the header and vertical members to accommodate rivet nuts.

The motor and closer subassembly was removed from the door operator. The operator has keyhole mounting holes in the base plate. This permits mounting screws to partially threaded, so the base plate was slid onto these four screws. Once in position, all of the mounting screws were installed.

For this push side of door installation, the 6060 heavy duty double lever arm was installed. The door opening ranges from 85 to 110 degrees in five increments. The arm shoe assembly has a spring buffeted stop. When the arm is mounted to the pinion, the pinion flat is opposite the arm marking. The arm shoe assembly should be perpendicular to the door face with the main arm at a slight tilt.

RF Door Switches

At this point, the Norton 6000 Series Low Power Door Operator is basically installed. The next series of steps is to install the two surface-mounted RF door switches. These activating door switches are powered by a 9 volt battery. The inside door switch was installed against the right vertical member at approximately 42" above the finished floor. The outside door switch was installed against the left vertical member.

Code requires the activating door switches to be mounted within one to five feet from the door. The door switch must be mounted where the user has full sight of the door but safely outside of the path of the door.

The next series of steps is to adjust the door closer power, backcheck position, backcheck, sweep and latch. The Norton 7500 door closer power is adjustable from size one to six. The backcheck position is adjustable from 90 to 75 degrees. To increase the backcheck, rotate the 1/8" hex wrench clockwise. To increase the sweep and latch force, adjust the valve counterclockwise. Without power, the door operator acts like a door closer.

There is no hard stop. Based on the location of the door and the age of the people using the door for access and egress, the operator can provide the backcheck.

For this installation, power was run prior to our arrival. The 6000 Series has connectors with terminal push buttons that are depressed to provide clearance for inserting the black and white wires. Be sure to attach the green ground wire.

An On/Off Power Switch is in the end cap closest to the hinges and a 3-position function switch is in the end cap closest to the latch. The three-position switch offers On, Off or Hold Open. Flip the three position switch to the Off position. Make sure the On/Off switch is in the Off position. Power the circuit. Flip the On/Off switch to the On position.

We programmed the closed and open positions. At this point the door is functional operable. Any further adjustments are fine turning.

For this installation, the opening speed was slowed to 80; the closing speed increased to 65 and the slow speed was unchanged. Door opening was adjusted to remain in the hold-open position for 10 seconds, sufficient time to accomodate a person using a walker. Because of the age of the residents, the screen display Push was left off, not activating Push and Go.

Once all the setting were programmed, the three-way switch was switched to the On position, enabling the door to shut. The door was tested a number of times by the residents to ensure the operation would accommodate their needs.

The final step was to attach signage, “CAUTION AUTOMATIC DOOR,” and a six-inch diameter round yellow background sign. A sign is to be mounted on each side of the door.

For more information, contact your local locksmith distributor or Norton Door Controls, 3000 Highway 74 East, Monroe, NC 28112. Telephone: 704-233-1589. Web Site: www.nortondoorcontrols.com.