Controlling Access With Magnetic Locks

The magnetic lock is a "Fail Safe" locking device that makes use of electro-magnet and an armature plate that are in contact when the door is closed. When powered, electrical energy creates a magnetic attraction, which causes the armature to bond with the magnetic lock face. If appropriate current is provided, the door will remain locked as long as power is applied. When power is cut to the magnetic lock, the door (armature) can be opened.

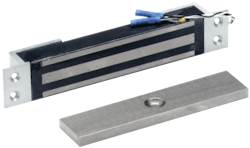

Electro-magnetic locks (magnetic locks) have no moving parts to bind or wear out. The electro-magnet portion consists of copper wire wrapped around ferrous metal plates in a non-conductive potting compound. These plates become magnetized when the appropriate current is applied.

Magnetic locks are relatively easy to install since they are standalone units. For a basic magnetic lock, only two wires are required to provide power. Properly installed and kept in adjustment, magnetic locks can have a very long operational life.

When installing a magnetic lock, the degree of contact between the magnet and the armature is critical. If the armature is in full contact with the magnet, the bond is the strongest, meeting the stated holding force. If the armature is slightly away or does not completely cover the magnet, the bond is weaker, possibly permitting the door to be unlocked.

In the past, some electromagnetic locks would create residual magnetism. The ferrous metal plates would become magnetized when there was no power. This would cause problems opening the door, as the residual magnetism would strengthen over time. As a result, Local Authorities Having Jurisdiction (LAHJ) would not permit the installation of magnetic locks because of the safety concern.

Over the years, lock manufacturers have developed different methods to eliminate residual magnetism. Release methods include patented instant release circuitry and a slightly raised screw that is above the face of the armature.

Magnetic locks are designed to be installed onto the secure side of a door. For outswing doors, the lock is installed onto the jamb header or jamb leg to the swing edge of the door. The armature is installed onto the door. For inswing doors, there are two top jamb mounting brackets. One bracket mounts between the lock and the jamb face. The other bracket is adjustable and mounts onto the door. It is offset to accommodate the additional space required for the lock and the armature. The lock is mounted onto the jamb.

Magnetic locks' holding force ranges from a few hundred pounds to thousands of pounds of dynamic holding force. For cabinet door locking, manufacturers recommend using a compact lock that produces about 300 pounds of holding force. An example of a compact magnetic lock face is about five inches long and one inch wide.

On the other end, the Securitron MM15 E-Mag has 4000 lbs. holding force. This hybrid magnetic lock has two spring-loaded, hardened steel jaws (mandibles). When forced entry is attempted, the mandibles rotate inward, trapping and clamping down on the edges of the armature, not permitting release.

For gate locking applications, magnetic locks are available waterproof, having a universal threaded conduit fitting and an extended length of jacketed conductor. For gate applications, the armature mount should provide additional shock absorption to help maintain proper contact and extend the operational life.

For swing entry doors, electromagnetic locks holding force are available from about 600 pounds up. The optimum holding force depends upon the application of the lock. Narrow stile glass aluminum doors and Herculite doors can provide sufficient holding force at the lower range of the magnetic locks.

For most applications, a 1,000- to 1,200-pound holding force electro-mechanical lock can provide sufficient holding force. These magnetic locks are available in different sizes to accommodate specific doorjamb configurations. For high security applications, magnetic locks range from 1,500 to 2,000 pounds holding force or greater. The strength of the door and jamb should determine the size of the magnetic lock.

Always remember that a magnetic lock requires power to remain locked. Loss of power unlocks the door, providing access to anyone. Backup batteries and/or ancillary locking mechanisms must always be considered when incorporating magnetic locks.

Consider the mounting location of the magnetic lock. For most applications, the magnetic lock is located along the top corner of the swing edge of the door. This is not a problem on most swinging doors at the minimum height clearance is 78". This takes into consideration a door closer installed into a standard seven-foot (84") opening.

Most magnetic locks are mounted onto the header, near the swing edge of the door. This can provide a security problem when using a magnetic lock as the only locking mechanism for a flexible door such as a glass aluminum stile. This type of door can possibly be bowed out from the bottom affecting the level of security.

Heavy gauge hollow metal or solid wood doors and solid jamb may not flex to the same extent, providing a more secure opening. However, repositioning the magnet or installing multiple magnets can provide the appropriate level of security.

A relatively new application has been introduced by Dortronics. The ML110 provides a unique method for securing an offset hung aluminum-glass or stile clad framed entrance doors using a magnetic lock on the exterior edge of the frame, having the armature mounted within the body of the pull handle.

A double magnet option is the Rofu 8122-002 that incorporates a full-length housing with one magnet at the top and bottom of the door. The 8122-002 provides 3,000 pounds holding force. The overall size of this double magnetic lock is 83" by 2-5/8" by 1-5/8". The housing is available in anodized extruded aluminum or stainless steel.

Because this type of magnetic lock is installed onto the swing side jamb stop, it will reduce the clear width of the doorway. According to the Americans With Disabilities Act (ADA) 4.13.5 Clear Width, "Doorways shall have a minimum clear opening of 32 in (815 mm) with the door open 90 degrees, measured between the face of the door and the opposite stop." For the Rofu 8122-002, it can only be installed onto doorways that have a clear width of about 35".

Other applications include traffic control, which is to provide a lesser degree of security during access periods. For a less expensive electronic access control, split armatures can be used with one magnetic lock to secure double doors. This lock is designed for traffic control double doors whose swing is in the same direction. The lock is installed in the center of the opening. The two armatures combined are the same length as a standard armature. One armature is installed onto each door. When power is removed, both of the doors can be swung open. The split armature option drops the cost as only one magnetic lock is installed. However, the locking mechanism is one half the holding force per door.

There are electromagnetic locks designed for sliding doors. Unlike swing doors, the sliding door shear style electro-mechanical locks can be installed in any position on or within the opening. This includes the top, side or bottom. To control the door's movement, the shear style locks have a restriction mounted into the armature and some models into the lock housing that extends into the armature, metal frame or body of the lock when energized preventing the armature from sliding off the magnet's face.

Delayed egress magnetic locks have built-in timers that delay the lock from unlocking for either 15 or 30 seconds once activated in accordance with NFPA 101. Fire code requires openings equipped with delayed egress magnetic locks to have a second release on the egress side of the door. Depending upon the location, it can either be a secondary button or exit device with external mechanical switch.

Magnetic locks come in three styles: the potted magnet, the locking mechanism installed within an outer housing and locks with a removable cover. The potted magnet style lock is non-handed. Some manufacturers offer different wire origination locations to accommodate specific applications. Potted magnet style locks can have mounting holes through the face and back or top and bottom. Other models have brackets attached to the sides. Options can include Door Position Switch (DPS) and Magnetic Bond Sensor. Options must be specified when the lock is ordered.

The development of the aluminum outer housing electro-mechanical locks included a separate mounting bracket, simplifying the installation. Some are equipped with a side compartment (wire chamber). These offset magnetic locks may be handed, as the housing cannot be reversed. Options for these magnetic locks can include Door Position Switch (DPS), Magnetic Bond Sensor, Adjustable Timer, Anti-tamper Sensor and Bi-color Status LED Indicator. The anti -tamper sensor indicates if the compartment cover is removed. Some side compartment equipped electro-mechanical locks have field installable options.

Over the last several years, architectural styled electro-mechanical locks have been introduced. These locks can have an extended cover providing interior room for options including passive infrared sensor (PIR) request to exit (REX), analog CCTV camera, LED indicators and REX output. When installing a PIR or CCTV camera, a continuous power input is required. Having more of the door components within the lock body can provide a "clean" appearance as well as being discreet, i.e. no visible camera.

Before installing a magnetic lock, it is important to answer the following questions:

- Is the opening fire rated?

- How much traffic flows through the door?

- Are there any other requirements from the LAHJ and building owner?

Make sure the electro-mechanical lock has the rating that meets these expectations. Some electro-mechanical locks have been tested and meet or exceed ANSI/BHMA A156.23 Standards. There may be state and city requirements. For example, the California State Fire Marshal (CSFM) has specific requirements. Know the ratings of the lock you are considering installing to be certain they meet all of the local, state and federal requirements.

Magnetic lock voltage is either AC and/or DC. The current can be fixed, field selectable or Voltage Sensing. Newer magnetic locks can require less current. The holding force and current requirements vary by manufacturer and model.

Dortronics 1000 Series Industrial Magnetic Lock has 1,200 pound holding force. These locks can be operate on either 12 or 24 VDC requiring 170mA @ 24 VDC or 340mA @ 12VDC to maintain the rated holding force. The 1000 Series has built in spike and surge suppression system.

The Rofu 8031 Shear Lock, a double magnetic lock, has 2,900 pound holding force and requires 1.7 Amp @12 VDC pull in, holding 0.5Amp or 1.1 Amp @24 VDC pull in, holding 0.32Amp.

The SDC EMLock 1580 Series magnetic lock has a 650 pound holding force. The DC voltage sensing input operates at 220mA @ 24VDC or 440mA @ 12VDC.

The Securitron MM15 E-Mag hybrid has a 4,000 pound Holding Force. The AC Current draw is 130mA max at 12VAC, 250mA max at 24VAC. The DC Current draw is 100mA max at 12VDC and 200mA max at 24VDC.

Warranties for magnetic locks vary depending upon the manufacturer. Some manufacturers offer replacement lifetime warranties. Contact the manufacturer for specifics.

Important: Before selling or installing any magnetic device, be certain to contact the Local Authority Having Jurisdiction (LAHJ) and any other authority who has authority to make a determination regarding the installation.

For More Information

The following is a partial list of magnetic lock manufacturers and their web sites. Visit Locksmith Ledger’s online Buyers Guide at www.locksmithledger.com/directory for complete listings.

Alarm Lock: www.alarmlock.com

BEA: www.beainc.com

Camden Door: www.camdencontrols.com

DORMA: www.dorma.com

Door Controls International: www.doorcontrols.com

Dortronics: www.dortronics.com

DynaLock: www.dynalock.com

Hager Companies: www.hagerco.com

Marray: www.marray.com

Rofu: www.rofu.com

RCI: www.rutherfordcontrols.com

Schlage: www.schlage.com

SDC: www.sdcsecurity.com

Securitron: www.securitron.com

To read additional Locksmith Ledger stories on mag locks, visit http://tinyurl.com/maglock614