Marray, Inc. designs and sells factory direct electrified UL listed access control locks, electric hinges, (UL 10C Fire Listed Electrified Hinge) electronic panic exit devices, fire listed electrified storefront and offset pivots, power door loops (armored door cords), REX switches and related equipment. Their trade names are Dor-Cor (to drill fire doors), Perfect Raceway and RediRex.

Marray has been a name-brand door hardware modifier for over 15 years. Their patented products have helped users of access control locking hardware realize significant savings, while at the same time, spending less time on a jobsite to accomplish their installations. They have over 15 patents in the electronic security lock hardware business.

Since all businesses are concerned with lower costs, faster implementation of projects and reliability of any purchased products, Marray has made it a core business strategy to only release products into the marketplace that are rigorously beta tested in actual field installations.

As a direct sale manufacturer, Marray is able to offer the best prices and support on electrified hinges, access control products and everything they offer.

Q & A: Ray Zehrung

We interviewed Marray President Ray Zehrung to learn more about the company and its products.

Can you us a little about your companies?

Around six years ago, I also co-founded the International Fire Door Inspector Association, the leading association in the world for people who want to learn how to inspect fire doors to the newest code requirement. Many people don’t know, but over 40 US states have adopted the NFPA 80, 2007 edition, which requires fire doors in local jurisdictions, to have annual fire inspections performed. The association is a great place for people to learn, bounce ideas off of each other and grow this as a separate business, or as an additional revenue source for their on-going service business. We have a Facebook page, if anyone is interested in learning more: www.facebook.com/firedoorinspectors

I began my work in the access control and locksmith industry, when I opened my first locksmith business in the Silicon Valley of California, 25 years ago. After installing thousands of electric locks, hinges, magnetic locks and panic exit devices, I decided that I could contribute to the industry in a more meaningful way by designing my own electrified door hardware products. I set out to develop new ways of building electrified hinges, new ways of modifying locks to be electrified and new ways of installing these products. I wanted to be more efficient and to be able to put more money into my pocket-as a locksmith-and into the pockets of my fellow security company friends.

I founded Marray, Inc., in 1995, so we are coming up on our 21st year in business. We could only have come this far, due to the continued support of our fantastic customer base.

What are your primary products?

Our primary products are custom modifications to many of the industry leaders in commercial and high-end residential door hardware. We modify Baldwin, Schlage, Yale, Corbin Russwin etc. mortise locks and we also modify a few cylindrical.

We also have our own name brand cylindrical grade 1 lock and our own electrified hinge line. We make our hinges from scratch, so they are not modified hinges that have a tendency to rust over time-the finish is applied after we machine them. We also have the leading industry tool that allows installers to drill a wire chase into a fire rated door and have the door maintain its listing status. We accomplish this by having our customers attend the Intertek, S. A. class for my creation, the Perfect Raceway class.

About 20 years ago, I was installing an electric lock set into two stairwell doors in the same building. I hand drilled each door and put the locks in, cleaned up and left the job site. The building owner called me a few days later and said that local AHJ (fire chief) was red-tagging the building since I had voided the labels on the fire doors. After a whole bunch of wringing of hands and a special letter ‑ one that cost more than my entire job invoice ‑ from Underwriter’s Labs, I finally decided that something had to be done. I created the Dor-Cor Drilling Tool and after about 10 years, convinced Intertek, the owner of the Warnock Hersey label, to let me create a program whereby locksmiths could place a sticker on the door showing it had been modified by a qualified Raceway Installer. Sure enough, the program is a huge success, so much so that Intertek has based a few other programs off of my initial design. I’m simply glad that my brothers-in-industry are able to do this type of work and not have to pay a door company, or have the doors replaced with factory cored doors. It’s worked out very well and the program is growing everyday. If anyone wants to check this program out, they can go to www.whmark.com/raceway for more information. There’s a listing of class dates and other pertinent information.

Who are your primary customers?

We don’t have a set type of customer, since we have a very strong multi-media and online presence. We might get a one-time purchase from a home owner who wants to electrify his gate entry; or we might get a contractor who had never heard of us, until he received the submittals for a construction project and found out that we were specified without substitutions.

Our mainstay is the professional locksmith and access control and security companies. We also have some great relationships with universities and occasionally, we have some sales to wholesale houses. We know that having a profit margin for our resale customers is important, so our web prices are for the public, but our customer who are in the business of resale, can create an online account and see significant savings. www.marray.com

Do you perform upgrade services as well as sell new products?

RZ: We do provide upgrade, or modification services to our customer’s hardware. It really depends upon what they want. We can do a simple modification to electric undogging, or we can install micro switches that allow for a mortise lock to send a multiple of signals.

What are some of your new and most unique products?

We have developed a very good method for modifying storefront door pivots, both top and offset. Our process is very durable and we have put these products through an exhaustive testing period, as well as having them in the field without complaint. Although we have had pivots for a very long time, these new top and center pivots are much better than anything else we know of on the market.

What code compliance issues and deployment issues may be associated with electrically upgrading hinges?

There absolutely are issues with modifying a door to take an electric hinge and lock. Most of the compliance issues are for commercial hardware, since even if the garage door in someone’s home is a typically two hour rated door, many AHJ’s don’t go to residential jobsites to make sure that fire doors have not been modified. However, on a commercial, industrial, healthcare, university project, you can be sure that many more AHJ’s are aware of the process for installing electrified access control hardware and if those doors are listed and labeled, they will inspect and if they find the job has been done without listing agency authority, they will cite you. Better to do it right the first time.

What code compliance issues and deployment issues may be associated with electrically upgrading lever trim?

Same issue, except for the added issue of putting in a piece of hardware that does not have the standard door face pattern. In other words, some wireless and standalone locks have extra wires that need to go through the door, to a battery pack or logic board on the inside of the door. In order to run those wires, the door might have to be modified. Well…if you modify the face of that door, for any purpose other than what the Code allows (cylinders, peep holes etc.), you have voided the label and will have to pay a substantial fee to a field inspector for a listing agency. So, before any modifications are made to listed and labeled openings, always check with the manufacturer and always check with UL or the listing agency used by the hardware manufacturer. If you go to www.UL.com, you can look up the listings for people and it will give you some information. You can also ask a UL representative if installing in the field voids the label.

What code compliance issues and deployment issues may be associated with electrically upgrading exit devices?

I used to modify a popular exit device, but once that company was acquired by a large multi-national, they cut off my supply, since they do not like anyone modifying their product. We are, however, working on a replacement and have been doing so for a few years. It takes quite a while to develop a good quality product, but we will launch when we are satisfied that it exceed our and our customers’ expectations.

Some electrified exits are solenoid operated while others use servo motors. Which do you recommend and supply?

I prefer solenoids. In my experience, the motors have issues and are too complex for mounting to something that experiences multiple surface shocks daily.

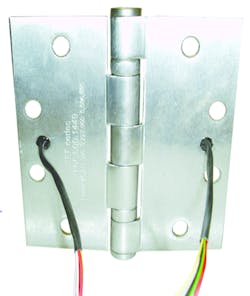

Electrified Hinges

This revolutionary hinge offers several advantages to the installer/customer. Two of the wires are heavy 18 gauge, silver coated, high conductivity Teflon jacketed conductors and four of the wires are 28 gauge, silver coated high conductivity conductors. The two 18 awg wires can be used with electric latch retraction devices, such as the Von Duprin EL 33 and 99 series panic devices. In fact, this EL hinge was engineered for just such uses. The smaller 28 awg wires can be used for controls and switches.

Not only is this PTH (Power Transfer Hinge) stronger and able to withstand more inrush than any other electric hinge on the market, but it is also independently tested to over 800,000 cycles on average before a wire breaks or goes to ground. That is 8 times the UL requirement of 100,000 cycles typical for most products on the market.

This hinge is also burn tested and UL10C listed for use on fire rated doors and frames. Marray was the first with such a listing.

After a standard hinge is modified, it no longer meets ANSI 156.1, or NFPA 80 and must be re-tested to ensure it will not default in a fire situation. Be sure when you order hinges for your listed doors that you install hardware that is fire listed. This will benefit you by ensuring that you do not de-listed and de-certified a fire listed door by not providing the proper listed hardware.

Most jurisdictions will begin annual fire door inspections under the 2007 edition of NFPA 80. If your hinge is not listed for fire, you may have to replace the door. Marray maintains a very large inventory of these hinges for same day shipment.

Low Voltage Rating:

- TEF2+4C, 16 amp surge, 5 sec., (18 awg pair) 12 or 24 Volt AC/DC, 100 m/amp 28 awg wires

- TEF10C, 1 amp one pair, 100 m/amp remaining pairs, 12 or 24 Volt AC/DC

- TEF2+10C, 16 amp surge, 5 sec., (18 awg pair) 12 or 24 Volt AC/DC, 100 m/amp 28 awg wires

Once you choose how many wires you would like, the Marray website will then take you through a series of options that will walk you down to the exact hinge you are looking for. Options after you click a wire designs will be Finish, Weight, Size and then Knuckle and Corner Style. Certain uncommon combinations may require special ordering.

Electrified Pivots

Marray is able to offer a UL 10C fire listed electric transfer intermediate offset pivot due to their unique PVD coating process. All Intermediate 3/4 offset Pivots are Stainless Steel base (for fire) and are custom-manufactured for Marray. You will not be able to tell the difference in the finish, since all finishes are BHMA compliant. They are available with high amp load wires (16 amp inrush) for use with Electric Latch Retraction Devices.

Electric Intermediate Pivots

Marray does not modify any pivots from other companies. They determined that manufacturing their own intermediate offset pivot to their own specification gave the best results. Most intermediate offset pivots are made from a brass or bronze base material. These materials are not suited for fire doors with ratings in excess of 20 minutes.

Additionally, once a listed product, such as a pivot or hinge has been modified from basic construction requirements (referenece ANSI 156.1 and NFPA 80), the product must be re-tested and listed as a new product category.

Marray is the only manufacturer of 3/4 offset electrified intermediate pivots whose products are listed for three hour (3 hour) fire rated openings.

Electrified Offset Storefront Intermediate Pivot

Marray's electrified offset storefront intermediate pivot is UL10C listed for fire doors. This 10-wire model is ideal for electric panic exit devices on pairs of wood, metal or aluminum doors equipped with 3/4 inch offset pivots where multiple switches are required for reporting functions.

All of Marray pivots are stainless steel base material, which is why they are able to be used in fire door situations of up to 3 hours. Marray is able to plate our pivots to any finish needed. Custom plating finishes are available as well.

With the requirement for annual inspections of fire door assemblies, be sure that any electric power transfer intermediate pivot you install is UL Listed for fire.

Brass or bronze based pivots that have been modified from the original construction must be re-tested and listed for the altered configuration.

Rating: 30 awg wires. 1 pair 1 amp 24 VAC/DC. 4 pair .10 amp 24 VAC/DC

Wire constuction: Teflon jacketed silver coated high conductivity copper stranded Mil-Spec wire.

Kanweer Electric Pivot

Marray takes these factory original Kawneer pivots and machines them on their Haas machine at their CNC center. Using CNC ensures all of parts are exactly the same and within close tolerance. This 10 wire Power Transfer Pivot is aluminum base material with proprietary Teflon jacketed wires.

This pivot can be used for electric latch retraction panic exit devices. The two heavy 18 awg wires will handle any electric latch retraction panic exit device on the market today.

If you are unsure as to which hand you need and you have an existing Kawneer mechanical pivot on the door, you can remove the pivot and look at the back. There should be a stamped or cast LH or RH on the back. If you aren't replacing a pivot and need one for a new job and are unsure of the hand, contact Marray tech support by calling 800.500.1449.

Marray Cylindrical Locks

This Grade 1 clutch lock is UL Listed for Fire Rated Frames and Doors. Clutch design resists vandalism and is very durable.

The lock can be ordered in a variety of styles, finishes and key configurations. It is available in Best IC prep and large profile Schlage IC.

All Marray cylindrical locks have Marray’s patented solenoid that is dual voltage and field changeable from EU (Fail Secure) to EL (Fail Safe) without hand tools.

For more information, visit www.marray.com