Door hardware has changed dramatically over the years, and institutional and commercial facilities are changing with it. Not long ago most door hardware was based on a simple cylindrical bore prep. With technological advances and a concentration in Access Control, today’s door hardware provides much more than simple passage. Today’s hardware provides restricted access, audit trails for added security, wired and wireless control, credentialed access through keypads, card, proximity, and biometric readers, and specific door functions based on a list of dynamic criteria.

In any type of building, installing upgraded security measures in door hardware can present significant challenges, especially in retrofitting existing doors in occupied buildings. Upgrading existing facilities can be especially overwhelming due to the limitations of existing borehole patterns on the door, limitations imposed by the existing building, such as frame or latch construction, and/or limitations imposed by the occupants working in the building.

There are also many factors to take in consideration when upgrading and retrofitting door hardware security. Hardware function, handed hardware, and aesthetics should always be considered. The upgraded hardware’s location point and the existing vertical and horizontal centerlines need to be considered to ensure the appearance of the hardware and the door were intended to pair together. Additionally, local and national codes must be taken into consideration.

Using the right tools can be extremely helpful in upgrading facility security to account for many of the unknown factors that can be present during a retrofit installation. These tools create the ability to save time, energy, and pay for themselves many times over by:

- Increasing the production rate,

- Increasing efficiency,

- Ensure high accuracy and precision,

- Reducing the production cost,

- Reducing quality control expenses,

- Reducing labor costs,

- Improving work safety.

PRO-LOK has designed tool solutions to make this process easy and seamless, eliminating the need to mark out and measure the hardware manufacture’s dimensions and locations. These solutions cut the hardware preparation and installation time to a fraction of the traditional method of using paper templates and freehand drilling. The use of a modular template system will provide a more accurate and efficient installation. The accuracy enjoyed by using this system will save additional time spent mounting the hardware. The elimination of hardware problems associated with inaccurate installations saves time, money, and energy in “call backs” and ultimately makes for better installation and satisfied customer.

PRO Installation Series Tools

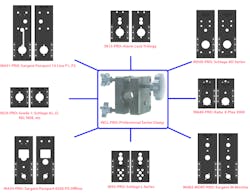

American-made PRO Series Installation Template tools are based off a traditional hub and spoke model. The INCL-PRO, Professional Series Universal Clamp, acts as the hub or core of the system, and the hardware-specific installation templates act as the spokes that use the hub.

This system is a modular one; once the INCL-PRO Universal Clamp has been purchased additional templates can be purchased at any time, as needed, and use the same INCL-PRO Professional Series Universal Clamp. This allows for fewer tools at a more economical price to ensure money savings.

This system is specifically designed to prep both the inside and outside of the door in one fixture to reduce the time and complexity of door preparation. The IN Series templates are exclusively sold in pairs to ensure time savings and include tool solutions for installing a variety of mechanical and electronic hardware including, but not limited to: Alarm Lock, Arrow, Corbin Russwin, Falcon, Kaba, Marks, Medeco, Sargent, Schlage, Von Duprin, Yale, etc. (Photos 1A and 1B)

The core of the system, the INCL-PRO Professional Series Universal Clamp, is specifically engineered to work with both beveled and non-beveled wood and hollow metal doors. The INCL-PRO tool is manufactured from military-grade solid aluminum with an anodized finish and is designed with three knobs that work independently of each other, each serving a unique purpose. The large knob is exclusively used to adjust for the thickness of the door, while the job of the two smaller knobs is to clamp the front and rear of the INCL-PRO and IN Series Templates (installation fixture) securely and flush to the door, independently of each other. The function of the two smaller knobs is similar to a cantilever, where these knobs control a mechanism that is basically fixed at one end and free on the other. This allows for an extremely secure and tight connection to the face of the door.

The INCL-PRO tool is also engineered to self-center on the latch side of the door, helping ensure proper drilling locations and reducing any adjustment needed, thus saving valuable time. (Photo 2)

IN Series templates are hardware- specific products based on lock manufacturer and hardware model design. The IN Series templates are designed utilizing true-sized holes, eliminating the need to mark pilot holes, remove the installation fixture, and then guess the size hole needed to be machined.

In addition to traditional bores, PRO-LOK solutions also account for non-traditional shapes and pathways for hardware features such as card readers, wire access slot channels, and door positioning switches. The openings on the template already account for what the hardware manufacturer intended and PRO-LOK accounts for the size of the door machining tools, such as bits or routers, being used. The result is a perfectly prepped door surface. These time saving features allow for every skill level of the installation crew to use these products, from the novice to the most seasoned installer. The less experienced crew members can be machining the door while the more advanced crew members can be installing and programming the hardware.

Additionally, this allows for repeatability and uniformed quality between doors, no matter who on the installation crew is doing the door preparation. This can be helpful when dealing with the local Authority Having Jurisdiction (AHJ), door relabeling, etc.

IN Series Templates also feature heat- treated steel bushings on most holes ½” or less, traditionally the largest twist bit size. These products are designed to work with hole saws, spade, spur, forstner, router bits, etc.

The IN Series templates are plug and play in the sense that after the unit is attached to the door, all of the critical door machining that needs to be done can be accomplished while the installation fixture is attached to the door. Once the installation fixture is removed, the door should be prepped properly to receive the flat plates and hardware components to complete the hardware installation.

Another unique feature of the IN Series tools are the way the installation unit mounts flush to the door. This important money-saving feature provides two unique benefits to the installer.

- It helps control for drilling errors by helping reduce bit movement during the door machining process. There is very little distance for the machining tool to travel from the installation template to door, which helps keep drilling bits straight and reduces angled drilling.

- Maintaining full and direct contact with the door helps preserve the integrity of the door’s finish. This feature helps prevent splintering or blowouts and reduces the chances expensive doors have to be replaced. (Photo 3)

Many times the hardware manufacturer’s desired dimension or path cannot be obtained by commercially available door machining tools, especially for some readers or wire access slot channels. PRO-LOK has solved this problem by manufacturing router guide bushings specific for the hardware application. This ensures the correct specifications are achieved. For the IN Series Templates that require one of these unique preparations, the guide bushings are included with the product.

Complete Installation Solutions

In 2009 PRO-LOK purchased the assets of MAG Manufacturing, and launched the ENTRY ARMOR brand. ENTRY ARMOR consists of staple security hardware products, such as wrap plates, latch protectors, strike plates, residential security products, and retrofit solutions such as adaptor plates, filler plates, and hole covers. These products help create the complete retrofit tool solutions needed to overcome many of the obstacles of upgrading security on existing doors in occupied buildings.

By expanding manufacturing capabilities, PRO-LOK is able to manufacture and provide the hardware preparation pattern not only in the IN Series Installation Templates, but uses the same preparation pattern for ENTRY ARMOR wrap plates and flat plates. These are great solutions to cover up the legacy preparation on the door, while exposing the preparation pattern needed to properly install the door hardware.

While the preparation pattern is available in both wrap plates and flat plates, many installers, integrators, and property owners prefer flat plates. If there is not damage to the door, as with most retrofit security upgrades, then there is not a lot of reason to add extra material to the latch side of the door. Many times, with the way doors and frames are constructed, there may not even be enough space to add extra material between the latch side of the door and the frame.

Aesthetically, flat plates look much better than a three-sided wrap plate and appear to integrate better with the door and door hardware. (Photo 4)

While door hardware will continue to change with security needs and technological advances, the tools that are available will ensure upgraded security measures will be easy to install and hardware will be properly functioning.