In this era of corporate takeovers, mergers, acquisitions and outsourcing, Hager is celebrating its 175th year as U.S.-based manufacturer, owned and operated by the Hager family. Hager has grown from forging wheel rims for Conestoga wagons to offering more than 6,000 door hardware products, including its flagship lines of hinges.

Locksmith Ledger asked the Hager family to list their milestone accomplishments.

- Made in the USA. There is a great sense of accomplishment in maintaining domestic production. Proudly manufacturing and distributing in Montgomery, Alabama with our dedicated and experienced workforce allows Hager to remain competitive and provide an exceptional level of service.

- A brand-new distribution center. Hager expanded the Montgomery production facility in 2020 to include a world-class distribution facility complete with a state-of-the-art, automatic storage and retrieval system (ASRS). The ASRS allows us to better serve our customers, and its modular nature allows for future expansion as dictated by the needs of our business.

- Our family culture. Over our 175-year history we have built a world-class culture and as a result have received numerous recognitions in “best places to work” publications. Our customers are the basis of our business, but our people are our greatest asset, and they are part of our family. We have stayed true to our roots, while remaining flexible to support the ever-changing needs of the markets we serve.

It wasn’t always an easy journey. Since Hager’s founding in 1849, the company has weathered two world wars, the Great Depression, numerous recessions and, most recently, the COVID-19 Pandemic and its related supply-chain disruptions. Hager has always emerged stronger on the other side, reducing hours but keeping staff employed during the Depression and producing hinges for the military in wartime.

More recently, Hager managed to navigate the workforce and supply-chain constraints that closed many businesses during the Pandemic. “We remained at full production while committed to protecting what is most important – our people, our customers, and the communities in which we do business,” noted President and COO Johnston Hager.

A Bright Future

Looking ahead, Bob Wilkins, SVP, Marketing & Product Development, sees the potential for adding new products to Hager’s extensive door hardware and electronic access control portfolio.

“Our traditional product offerings remain the core of our business and provide the quickest avenue for sustained organic growth. The door hardware market, however, is growing at a faster overall rate in the areas of electronic access control and electrified hardware. While we already have a large existing portfolio of such products, we have multiple resources dedicated to researching and launching new products and services to support this growth.”

The industry is clearly moving toward electronic control, and Hager will continue to adapt to these emerging technologies and develop solutions that are easy to install, commission, and deploy. Educating and training are also a priority as the industry evolves.

“We are deeply committed to educating our channel partners to the latest industry advancements whether it be through our relationship with the Door Hardware Institute or through Hager University and our Managed Services group. This education includes working within multiple channels to raise awareness around product choices, accessibility issues, and code compliance,” said Eric Rose, SVP Global Sales, Hager.

Hager is also committed to remaining an independent, family-owned business in this era of mergers and acquisitions. “Each generation is determined to leave the company better for the next generation. As a family-owned business, we are not susceptible to making hasty decisions to satisfy a large group of stockholders based on short-term market conditions. We have seen the many ebbs and flows of the hardware market for the last 175 years, and we have invested in the business as situations dictated. We remain focused on continuing that success with a balanced mix of short- and long-term goals,” added Johnston Hager.

The Early Days

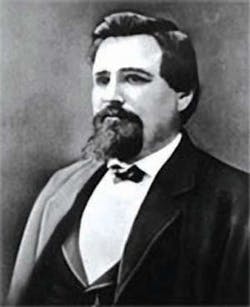

Hager founder Charles Hager left Germany in 1848 and later landed a job as a blacksmith in St. Louis. After taking over the shop a year later, he found his niche, forging wheel rims and hardware for settlers heading West in Conestoga wagons.

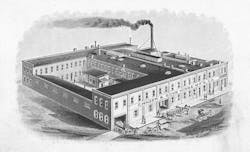

St. Louis grew, and so did the business. By 1878, the blacksmith shop had taken on a new look and a new name: C. Hager and Sons Hinge Manufacturing Company, specializing in the manufacture of quality hardware. In 1894, Hager began producing hinges for wooden beer cases for a brand-new St. Louis beer, Budweiser. The Anheuser-Busch brewery is Hager’s neighbor to this day.

In the early 1900s, Charles Hager stepped down from the presidency, and his son, August W. Hager, became the company’s 2nd president. It was during this time that the country saw rapid growth of both farm and residential construction. At that time, most hinges were produced by hand forging and other manual procedures. August Hager embraced the Industrial Revolution and modernized the manufacturing process.

The initiation of the Panama Canal Project by President Teddy Roosevelt further enhanced business as Hager was contracted to produce massive quantities of custom hinges for locks on the canal. Then, from 1914 to 1918, during WWI, government orders for hinges continued to flourish and keep the Hager factory producing at maximum capacity.

In 1929, August W. Hager passed away, and Charles A. Hager (another son of Charles Hager) became the company’s 3rd president.

Then came the Great Depression, which closed down many businesses, but Hager survived. As quoted from family archives by J. Withnell Hager, “We kept our organization together. We never closed. We worked half days instead of full days in order to give our employees some work. We kept going in spite of the fact that we were losing money. We stocked our inventories and kept our complete workforce intact. Hager employees have always been part of the family.”

During Charles A. Hager’s presidency, C. Hager and Sons Hinge Manufacturing Company’s sales tripled, and the company’s market share was significantly increased by the decision to sell through distributors.

In 1945, Archer L. Hager (Charles A. Hager’s son) became the company’s fifth president. Archer had started with Hager as a shipping clerk in 1912 when he was 18 years old. While working his way to presidency, Archer operated every piece of machinery in every department of the company.

World War II proved to be the next challenge for Hager and for the United States. While the Hager men served their country, the Hager women kept the business running, producing hinges for the military. Post World War II, Hager stepped up its manufacturing of commercial hinges and again modernized its factories.

In 1970, A. William Hager became the company’s sixth president and Hager relocated its manufacturing from St. Louis to new, modern facilities in Greenville, Mississippi, and Montgomery and Oxford, Alabama. This strategic move allowed Hager to streamline production with increased capacity and state-of-the-art machinery and processes.

Moving Beyond Hinges

Under the leadership of August W. “Rusty” Hager III, the company expanded its product line to include Roton continuous geared hinges, trim and auxiliary, and thresholds and weatherstripping products. In the 1990s, Hager added sliding door hardware to its product range.

As the 2000s began, Hager introduced stainless steel continuous hinges and that same year, Hager launched locks, door controls, and exit devices.

2008 saw the addition of electric locks and exit devices and also the launch of Euroline – a product line focused on meeting the needs of international customers. Hager products can be found in buildings throughout the Middle East (including the Burj Khalifa and Burj Al Arab in Dubai) as well as Central and South America, Asia, and North America.

Over the next decade, the product line continued to expand and welcomed the sixth generation. Johnston Hager started out as Product Manager for architectural hinges and thresholds & weatherstripping. Continuing his growth within the company, he was promoted to Director of Residential Sales.

August Hager (Rusty’s son) joined Hager as an Architectural Specification Associate. August became the first Hager to obtain his Architectural Hardware Consultant (AHC) through the Door & Hardware Institute (DHI).

In 2012, Hager launched a line of electrified products, low-energy power operators and actuators, the Hager H family of keyways, the 2300 Series deco leverset and large format interchangeable cores to work in conjunction with the Grade 1 cylindrical leversets, mortise locks and exit device trims. Keeping safety at the forefront, Hager added a photoluminescent push bar cover option, an optional flush end cap, and anti-vandal pulls to the exit device product category. Hager also added the 9400 Series stainless steel sliding door hardware to the sliding door product line.

In 2017, Hager forged an alliance with Salto Systems, launching Hager powered by Salto, a new product category for electronic access control. The HS4 platforms provide solutions for the entire building and adapts easily to evolving requirements and budgets for a multitude of vertical markets including multi-family, assisted living, education and healthcare.

Next came 3300 Series Grade 3 leversets. Hospitality transitional thresholds, sliding barn door privacy locks, the eConestoga economical sliding door hardware and the door cushion stop were added to the sliding door hardware product line. New power supplies and door prop alarms were added to the electronic product line, and the BLUEnet, Interconnected GEO, KS Platform, and the AElement were added to the HS4 electronic access control product line.

In 2019, new safety features for Roton Continuous Geared Hinges were launched, including the TIPIT Ligature-Resistant Hospital Tip and a newly improved Hospital Tip. The 8300 Series was added to the low-energy power operator family to provide ADA compliance to both interior and exterior door openings.

Warren “Sonny” Hager Jr. began working at Hager. August Hager IV was promoted to strategic account executive.

The company began modernizing and expanding its manufacturing and warehouse operations in late 2019. An existing warehouse in Montgomery was replaced with a new distribution center and state-of-the-art Automated Storage and Retrieval System (ASRS).

Post-Pandemic Growth

Despite the challenges of the COVID pandemic, Hager remained focused on customers and product development. COVID provided numerous challenges, but as usual, the Hager team was up for the task and focused on filling customer orders by navigating the many supply chain and material issues. Continued product expansion included additions to the Locks, Door Controls, and Exit Device categories in addition to product development around hands-free solutions. Hager also began work on revamping the sliding door hardware line to provide an expanded yet streamlined product offering.

The new distribution center was completed in the fall of 2020 and the transition to the new warehouse and software system began. In 2021, Sonny Hager transitioned to the product manager for threshold and weatherstripping. The following year Johnston Hager was promoted to the position of president and chief operating officer. In his prior role as senior vice president of residential sales, national accounts and customer support, Johnston was instrumental in driving customer relationships and reorganizing Hager’s customer support team. August Hager IV, A.H.C. has expanded his role as sales manager for Hager’s Southeast region and remains Vice President of Technical Services.

Read a full history of Hager on their website at https://www.hagerco.com/web-page-links/hager-history

Hager Timeline

1848: Charles Hager left Germany, eventually ending up in St. Louis and going to work at a blacksmith shop. A year later, he bought that shop.

1878: The blacksmith shop became C. Hager and Sons Hinge Manufacturing Company, a family business specializing in the manufacture of quality hardware.

1894: Hager began producing hinges for wooden beer cases for a brand-new St. Louis beer: Budweiser.

Early 1900s: Charles Hager stepped down from the presidency, and his son, August W. Hager, became the company’s second president.

1904-1914: Hager was contracted to produce massive quantities of custom hinges for locks on the Panama Canal, under construction at that time.

1914 to 1918: During World War I, government orders for hinges kept the Hager factory producing at maximum capacity.

1929: Charles A. Hager (another son of Charles Hager) became the company’s third president.

1930s: Through the Great Depression, Hager never closed, working shorter days and losing money but keeping their workforce intact.

1943: Richard G. Hager (another son of Charles Hager) became the company’s fourth president.

1945: Archer L. Hager (Charles A. Hager’s son) became the company’s fifth president.

1945: With its president and top executives serving the country in World War II, C. Hager and Sons Hinge Manufacturing Company remained in business, producing hinges for the military, run by the Hager women.

1970: A. William Hager, became the company’s sixth president. Hager relocated its manufacturing from St. Louis to new, modern facilities in Greenville, Mississippi, and Montgomery and Oxford, Alabama.

1985: A. William Hager became Chairman of the Board and his eldest son, August W. “Rusty” Hager III, became the company’s seventh president.

1985: Hager expanded its product line to include Roton® continuous geared hinges, trim & auxiliary, and thresholds & weatherstripping products. In the 1990s, Hager added sliding door hardware to its product range.

2003: Hager Companies transitioned presidency from Rusty Hager to Charlie Hager (Rusty’s cousin), making Charlie the company’s eighth president. This decade also began with the introduction of Hager’s stainless steel continuous hinges.

2006: Hager transitioned presidency from Charlie Hager to Ralph Hager (Rusty’s brother. Ralph became the company’s ninth president.

2008: Hager launched three new product lines – Locks, Door Controls, and Exit Devices. The company also launched Euroline – a product line focused on meeting the needs of our international customers.

2009: Hager consolidated its Oxford and Montgomery, Alabama, manufacturing plants and opened a new distribution center in Phoenix, Arizona.

2010-2015: Hager launched a line of electrified products, including electric strikes, keypads, and magnetic locks followed shortly by the 8400 Series Low Energy Power Operator. The expansion also included the Hager H family of keyways.

Johnston Hager was promoted to Director of Residential Sales. August Hager (Rusty’s son) joined Hager as an Architectural Specification Associate. August became the first Hager to obtain his Architectural Hardware Consultant (AHC) through the Door & Hardware Institute (DHI).

2019: Warren “Sonny” Hager Jr. began working at Hager. August Hager IV was promoted to strategic account executive.

2020: COVID provided numerous challenges, but the Hager team was up for the task and focused on filling customer orders by navigating the many supply chain and material issues. Continued product expansion included additions to the Locks, Door Controls, and Exit Device categories in addition to product development around hands-free solutions. Hager also began work on revamping the sliding door hardware line to provide an expanded yet streamlined product offering.

2020: The new distribution center was completed in the fall of 2020 and the transition to the new warehouse and software system began. The company had begun modernizing and expanding its manufacturing and warehouse operations in late 2019 with a $20 million investment in this new distribution center and state-of-the-art Automated Storage and Retrieval System (ASRS).

2021: Sonny Hager transitioned to the product manager for threshold and weatherstripping.

2022: R. Johnston Hager, III was promoted to the position of president and chief operating officer. August Hager IV, A.H.C. has expanded his role as sales manager for Hager’s Southeast region and remains Vice President of Technical Services.

Emily Pike | Managing Editor

Emily Pike is managing editor of Locksmith Ledger International.