Beyond Security: Unlock the Potential of Exit Devices

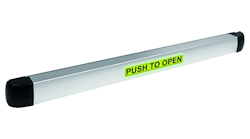

The concept of the exit device has been around for more than a century. A number of fatal fires in the early 1900s prompted the creation of new building regulations in the United States. And by the end of the 20th century, most countries had implemented codes that required buildings to have a certain number of fire exits. In many cases, these emergency exits were outfitted with exit devices that allow many people to pass through the opening at speed.

Today, however, exit devices do so much more. While safety and security continue to be priority outcomes of these devices, advancements in technology and access control over the past two decades have spurred an evolution in capabilities. Those involved with designing, constructing and managing facilities can leverage these advancements in many ways that can benefit a building. Let’s explore three ways that an exit device can improve outcomes at points of egress.

Easier Access for All

Beyond security, exit devices provide accessibility that other solutions can’t match. They need only a single motion to operate, making them typically easier to use than door handles or pulls that require multiple motions. Additionally, updated regulations are beginning to be implemented across the U.S. to make the operation of exit devices even more effortless. California, for example, has adopted the American Disability Act standard, which requires the latch of an emergency exit device to release with five pounds of force or less, significantly lower than the 15 pounds required by other widely used standards. Many other states are also working to implement the 5-pound requirement.

The single motion and low effort required of an exit device make opening the door easier for children, senior citizens and those with disabilities. As a result, exit devices are a particularly good option for access points in schools, hospitals and other healthcare facilities, not just for the obvious security they provide, but because they make moving from point to point within a building easier for all.

Functionality at the Touch of a Button

Today, wireless innovation enables new possibilities for managing exit devices, such as remote control, monitoring and other functionality. For example, motorized latch retraction and monitoring capabilities allow remote dogging and un-dogging of exits. In emergency situations, the ability to remotely control exit devices in a facility could make a life-saving difference by ensuring occupants get out of the building as quickly as possible while limiting the access of the attacker.

Greater Energy and Cost Savings

Thanks to a growing number of power options, exit devices are becoming increasingly energy efficient. For example, low-power motorized latch retraction devices can deliver electricity savings of 50 percent or more per activation. With these solutions, efficiencies are gained because no power is required to secure the door. Without power, the latch in the exit device extends, keeping the door shut. With power, the latch retracts, allowing the door to swing open.

As consumers continue to demand more sustainable environments and facility managers look for new ways to streamline spend, the potential energy and cost savings that exit devices can deliver will only grow in importance.

Exit devices have long been viewed as a dependable workhorse that provides security. But today, security only scratches the surface of outcomes exit devices can drive. Easier accessibility, improved functionality and energy and cost savings are a few of the benefits exit devices deliver. And these possibilities are only the beginning. As access control continues to advance, new capabilities of exit devices will become reality and create even greater outcomes for securing and managing the facilities we use every day.

Sylvons Iyavoo, as ASSA ABLOY’s Senior Product Manager, is responsible for identifying and defining emerging trends for product management and driving product innovation for Adams Rite range of products. Sylvons has extensive experience in the physical security industry and held several different roles across Americas, Europe and Asia. He is an ASSA ABLOY certified lean innovation champion and holds a Bachelor of Mechanical Engineering degree from Anna University, Chennai.