Steelcraft has eliminated contractors from having to apply traditional tar-like, foul-smelling, hazardous bituminous coatings on grouted masonry frames. Instead, Steelcraft has introduced a new better, safer, easier-to-use Frame Back Coating that is UL-certified for 3-hour fire-rated masonry applications. In addition to being non-flammable, the coating is virtually odorless, provides strong adhesion, dries quickly and won’t easily rub off as the frame is transported to the jobsite. Contractors can apply the Frame Back Coating in their shop or at the site.

“Typically, contractors have grouted masonry frames in openings that are heavily used, need sound insulation or require stronger anchorage reinforcement,” explains Ken Richied, Steelcraft product manager. “The mortar mix along with environmental factors can corrode the frame throat. Now, instead of using hazardous, difficult to apply, flammable bituminous coatings, they can use Steelcraft’s new Frame Back Coating which helps resist corrosion without compromising the opening or the contractors who apply it.”

Being UL-certified for 3-hour, fire-rated masonry applications means architects can finally specify the coating and grouting of masonry frames in fire-rated openings, a benefit that is not possible with traditional bituminous coatings. The Steelcraft Frame Back Coating is also free of both Volatile Organic Compounds (VOC) and Hazardous Air Pollutants (HAPS), making it much safer to employ and use.

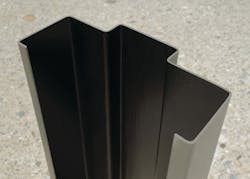

The Frame Back Coating is thin and fluid-like. It creates a black, semi-gloss finish. Available in aerosol cans and 1- or 5-gallon pails, it can be sprayed or brushed. A waterborne material, clean-up is much easier than dealing with the gooey consistency of traditional bituminous coatings. Shelf life is 12 months.