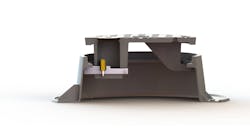

The Rutherford Controls Int’l (RCI) Early Warning EM (Electro-Magnetic) Lock provides the additional benefit of notifying when forced entry is being attempted. The RCI Early Warning EM Lock, part number EW8310, is UL Listed, has a Security Condition Sensor (SCS) that indicates when the door is closed and properly bonded, auto sensing voltage from 12 to 24VDC, low voltage detection and up to 1200 pounds of holding force. The current requirement is 0.58Amp @ 12VDC and 0.29 Amp @ 24VDC.

This Early Warning EM Lock has a patented, built-in sensor that detects when 55 pounds or more of force is applied against the electromagnetic holding force. The 55 pounds requirement limits false alarms that can be initiated accidentally, or by means such as the building’s air system creating a vacuum effect on the perimeter doors. This sensor can then activate a local and/or remote alarm dry contact relay switching (SPDT and DPDT), and an optional buzzer prior to the door being compromised.

A six- inch light panel built into the front of the magnet indicates status. When the door is secure, the light panel flashes green every five seconds. When access is granted, the magnet is de-energized and the door is opened. The light panel will illuminate red. The light panel will remain red until the door is closed and the magnet bonds with the armature plate. If someone attempts unauthorized entry, the light panel flashes red and the lock enters the first of three alarm conditions.

The first alarm level is the four-second Nuisance Delay, which occurs when the pressure is first exerted. The light panel will rapidly blink red and the local alarm relay will be energized. An external buzzer will emit a pulsing sound indicating someone is attempting to gain entry. If the pressure is withdrawn within the four seconds, the Early Warning Magnetic Lock returns the normal condition. The Nuisance Delay is in case of accidental contact with the door. This way the door can be bumped without activating an alarm.

If pressure continues for more than four seconds, the EW8310 will enter the Remote Alarm Period for 30 seconds. The remote alarm relay will remain energized. The light panel will slowly blink red and an optional external buzzer will emanate a continuous sound. If the pressure is withdrawn within the 30 seconds, local and remote alarms relays will return to the normal condition. However, the light panel will continue to flash red and green, indicating a serious attempt has been made. The magnet must be manually reset to return to the normal condition.

If an entry attempt stops and is reapplied once tampering has extended beyond the four seconds, the Early Warning EM Lock goes immediately to the Remote Alarm Period and both the local and the remote alarm relays energize.

If an entry attempt continues and the door is forced open, the light panel rapidly blinks red. The optional external buzzer emanates a pulsing sound and the local alarm relay is energized.

Even if the door is then closed, the alarms and buzzer (if equipped) will remain activated until the power is turned off.

This precautionary technology provides an opportunity to circumvent forced entry. As a secondary benefit, the RCI Early Warning EM Lock can be used as a standalone recording lock mechanism or incorporated into an access control system.

On specific days of the week, a company rents the forward portion of the clinic. The forward portion of the building is separated from the rear portion by two corridors. The main corridor has a separating door that is in swinging. The secondary corridor is equipped with keyed levers locks at each end.

The front portion of the building houses the reception area, offices, examination, procedure rooms and three marked exits. The rear portion of the building has two marked exits.

For this installation, the RCI Early Warning EM Lock will be used as an access control device in a medical clinic that takes the entire building. The Early Warning Magnetic Lock will be installed onto a non-fire rated/non-latching door that separates the front portion of a medical clinic from the rear.

The local authority having jurisdiction (LAHJ) permitted this installation as long as the EM lock was interfaced with the Fire Alarm Control Panel. Should a fire occur and the alarm activate, the Fire Alarm Control Panel will de-energize the EM lock.

The purpose of the Early Warning EM Lock is to not only separate the two portions of the building, but also to let the owner know if an unauthorized person has attempted entry into the rear portion of the building. The electrical room is in the back half of the building within approximately 40 feet of the door.

The magnet will be installed onto the forward side of the door adjacent to the door closer. This way should someone tamper with the door for more than four seconds, the very visible light panel will flash red and green until reset. To reset, access must be gained into the rear portion of the building.

For this installation, the equipment installed in addition to the Early Warning EM Lock is:

RCI Key Switch (part number R960NMA)

RCI Power Supply (part number 10-175UL)

RCI 12VDC 4AH Sealed Batteries (part number BB12-4)

22 AWG cable

The RCI Key Switch has a 1-5/8” x 4-3/4” extruded aluminum beveled edge plate that is ¼” thick. The switch is equipped with a SPDT maintained switch used to energized and de-energize the EM lock. Tamper-resistant screws are included.

An RCI 10-175UL power supply provides 1.75 Amps continuous filtered and regulated current output @ 12 or 24VDC. This UL Listed power supply is equipped with a latching fire alarm tie-in with manual reset.

In case of power loss, two sealed batteries were included to provide sufficient power for the building management to arrive.

The medical clinic has drop ceilings, making the wire runs easier. A finish wall separates the front portion of the building from the rear with drywall from floor to roof.

Wire runs required for this installation include:

110VAC to the power supply

A pair of wires from the power supply to power the Early Warning EM Lock

A pair of wires from the power supply to the key switch

A pair of wires from the power supply to the fire alarm panel.

The installation was straightforward. The building is relatively new, meaning the panels did not contain asbestos and could easily lift out of the way. We lifted about six panels to run the wires from the power supply to the door area. A hole was cut in the drywall for the key switch and to run the wires.

Power was available in the electrical/computer room for the power supply. The fire panel wiring was made available.

The included paper template for the armature plate and the EW8310 was used to roughly locate the EM lock. Three holes were drilled for the armature plate. Each hole was pilot drilled into the laminate faced wood door using a small diameter drill bit to prevent splitting. The sex bolt pilot hole was drilled slowly to prevent splitting as the bit pierced the back face laminate. The holes were drilled to their required sizes and depths.

The EM lock mounting bracket is handed and must be installed in the proper direction and position. The mounting bracket must be installed with the opening for the wiring on the same side as the cutout in the case. In addition, the mounting bracket must be positioned with the cutouts in the wider slot to hold the lock by the screws.

The mounting bracket has two narrow oval slots to pre-position the unit for installation. Once the two holes were drilled, and screws temporarily installed, the mounting bracket could be re-positioned by locating the EM lock against the armature plate.

Two wider oval slots in the mounting plate are used to locate the EM lock. These slots accommodate the two screws threaded into the lock case. Loosen the two screws and position them beneath the open end of the wider slots. Lift the lock until the screw heads are in the slots above the bottom of the mounting bracket. Slide the lock towards the door. The lock should be held onto the mounting bracket.

To ensure the EM lock was securely attached, 11 TEK™ screws attached the mounting bracket to the header. Although TEK screws were provided, each of the holes was first center punched and a 1/8” pilot hole was first drilled.

The only drawback mounting the EM lock was the thickness of the Timely Frame. However, there was built-in re-enforcement for the door closer arm that ran along the header.

Four hex head screws secure the EM lock to the mounting bracket - two on each side. Holes in the bottom of the lock case allow tightening or loosening the screws.

However, the cover plate screw and the screw on the other side of the EM lock face obstruct access to the four hex head screws used to secure the lock onto the mounting bracket. RCI supplies four slugs that can be pressed into the bottom of the EM lock case.

For more information, contact your local locksmith distributor or Rutherford Controls Int’l Corp. 210 Shearson Crescent, Cambridge, ON Canada N1T 1J6 or 2697 International Parkway, Pkwy 5 Virginia Beach, VA 23452. Telephone 519-621-7651. Web Site: www.rutherfordcontrols.com.