Commercial applications for electric strikes have expanded to accommodate just about every type and style of door lock mechanism. In a world moving towards “micro-managing” access control and auditing who gains access, multiple lock hardware choices give locksmiths the ability to custom configure a system to accommodate the end-users’ requirements and finances.

The development of the electric strike for rim exit devices required building an electric strike body that was at least partially surface mounted to accommodate the Pullman style latch. For rim exit devices equipped with a Pullman style latch, the mechanical strike is surface mounted, extending out from the jamb face. Unlike a latch or deadbolt, a Pullman Latch is radiused and pivots like a butt hinge. When locked, the tip of the Pullman latch extends in front of the strike, stopping the door from swinging open.

The electric strike has been around for more than 120 years. A “no cut” or complete surface mount electric strike does not require a cutout in the jamb or within the jamb or the wallboard material to accommodate the body of the electric strike. These “no cut” or complete surface mount electric strikes have become a viable choice for installation onto fire rated openings.

The minimal projections of the ½” and ¾” thick electric strikes enable them to be used with rim exit device applications where the lock side of the door and jamb area has limited space. In addition, spacers are available for exit devices where there is more than sufficient space between the exit device and the electric strike.

At least three electric strike manufacturers offer completely surface mounted electric strikes. They are HES (9600, 9500 and 9400), Rutherford Controls Inc. (0162) and Trine (4800, 4801 and 4850).

Important: Before installing the electric strike, make sure the door operates properly and the door closer closes the door. If not, make all necessary repairs before installing an electric strike.

HES 9600, 9500 and 9400

In 2000, HES introduced the 9600 Genesis electric strike. The 9600 is designed to operate with most rim exit devices equipped with Pullman latches having up to a ¾” throw without modification. The patented 9600 meets or exceeds the ANSI/BHMA A156.31 Grade 1 specification. It is UL 1034 burglary listed.

The HES 9600 is completely surface mounted. The 9600 stainless steel faceplate is approximately 9” high by 1-3/4” wide by 3/4“ thick. This non-handed electric strike can be installed onto metal or wood jambs. The continuous duty operation solenoid is field selectable, operating at 12 or 24VDC. The draw for 12VDC is .45 Amps and 24VDC is .25 Amps. The HES 9600 is field selectable; the electric strike can operate as Fail Secure or Fail Safe.

The 9600 incorporates two stainless steel, independently operating locking mechanisms. Two stainless steel keepers, one at the top and one at the bottom, secure the latch opening. Each stainless steel keeper operates independently and is designed to secure a Pullman latch, keeping the door closed. The 9600 static strength is 1,500 pounds with a dynamic strength of 70 ft-lbs.

When the electric strike is unlocked, the stainless steel keepers swing out as rim exit device’s extended Pullman latch moves out of the electric strike’s opening. Once the Pullman latch has swung beyond the keepers, the spring loaded locking mechanisms retract them to the locked position re-creating the strike enclosure.

The HES 9500 is the fire-rated version of the 9600 electric strike designed to accommodate up to ¾” Pullman latches. This electric strike is UL 10C fire-rated for 1-½ hour in Fail Secure operation only. It is Fire Door Listed with Warnock Hershey (Intertek). The 9500 is fire door conformant according to CAN4-S104, NFPA-252, and ASTM-E152.

The HES 9400 Series completely surface mounted electric strike is designed for a ½” throw Pullman latch equipped rim exit devices. The 9400 meets or exceeds ANSI/BHMA A156.31 Grade 1 specifications and is UL1034 burglary listed.

The HES 9400 is constructed of stainless steel with a removable cover that conceals the mounting screws. Four screws secure the cover to the electric strike body. Operational features of the 9400 are very similar to the 9600 except for the Pullman bolt throw that can be accommodated.

HES 9600, 9500 and 9400 electric strikes use plug-in connectors for the electrical connections. These include the SMART Pac™ II Power Controller, the Plug-in Bridge Rectifier, and the Plug-in Buzzer. The SMART Pac II Power Controller provides electronically regulated current from 12 to 32 volts for continuous duty operation without normal heat build-up. An adjustable minimum activation timer is built into this in-line power controller, as well as an in-line fuse and M.O.V. that protects the host system from reverse current surges.

HES electric strikes are equipped with elliptical shaped mounting holes. This enables horizontal adjustment of the electric strike body in order to alleviate pre-load.

Optional electronic features for the HES 9600, 9500 and 9400 electric strikes are latch bolt monitor and latch bolt strike monitor.

The HES 9600, 9500 and 9400 electric strikes come with a five-year limited warranty.

RCI 0162

The Rutherford Controls International Model 0162 surface mounted electric strike is designed for hollow metal, aluminum and wood door frames. The patented RCI 0162 is constructed with a stainless steel housing that is reinforced to eliminate twisting in case of imperfect frames. It meets or exceeds ANSI/BHMA A156.31 Grade 1 specifications and is UL1034 burglary listed. The 0162 has been factory tested for more than 4 million operational cycles and a keeper strength of more than 2,200 pounds.

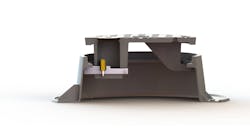

The non-handed RCI 0162 is completely surface mounted. The contour shaped stainless steel body of the 0162 is 9” tall by 1-3/4” wide by 3/4“ thick. The one piece stainless steel “rolling” keeper is approximately 1-½” tall. The keeper accommodates Pullman latch exit devices with latch projections from 1/2” to 3/4” from most major exit device manufacturers. It is designed to provide even load distribution in the event of an attempted forced entry.

The RCI 0162 electric strike has two sets of mounting holes. The top and bottom holes are horizontally oblong in order to ensure proper latch alignment with up to 1/4” horizontal adjustment to compensate for misaligned doors. The two center lock down holes are for additional mounting to ensure the electric strike will stay secured onto the jamb in the event of attempted forced entry.

The Fail Secure coil is horizontally mounted to prevent manipulation from vibration. The armature of the coil provides more efficient movement for locking the keeper. In addition, a horizontally mounted coil is not affected by the handing of the electric strike.

The field selectable input is 12 or 24VDC or 11 to 24VAC. A four-wire lead extends from the electric strike. Two two-wire connectors are provided for the different voltages.

Alternating Current coils are for intermittent duty where the coil is energized for less than one minute. Direct Current coils are continuous duty and can be energized for more than one minute. AC powered coils emanate a buzz when powered. The RCI 0162 can accommodate intercom voltage of 16VAC to operate electric strike to provide common door or gate access.

Note: The 0162 can be equipped with a DC coil and unlocked by powering the coil for extended periods of time. If power is lost, the exit device becomes locked maintaining security.

For proper operation, there must be 1/16” horizontal clearance between front of the Pullman latch and the electric strike to avoid pressure on the keeper.

A 3/16” Allen Wrench is included to secure the four included mounting screws.

Accessories for the 0162 include a double door housing and a 1/16” mounting spacer kit.

The RCI 0162 has a five year limited warranty.

TRINE AXION 4800, 4801 AND 4850

The Trine Axion 4800 and 4850 are completely surface mounted electric strikes designed specifically for Pullman Bolt equipped rim exit devices. The Trine 4801 works with Corbin Russwin SecureBolt™ and Yale SquareBolt® Exit Devices. These two rim exit devices are equipped with a plunger type latch bolt, not a Pullman latch. The Trine Axion 4800 is designed to operate with up to a ¾” throw Pullman latch without modification. The Trine Axion 4850 is designed to operate with up to a ½” throw Pullman latch without modification.

According to Trine, these BHMA Grade 1 rated electric strikes have each been tested to one and one-half million plus cycles. The 4800 and 4801 provide a holding force of 3,000- plus pounds. The 4850 provides a holding force of 1,500- plus pounds.

The Trine 4800, 4801 and 4850 lock mechanisms are two stainless steel U-shaped latches that form a rectangular pocket when the electric strikes are in the locked position. As the door closes, the Pullman latch, the SecureBolt and the SquareBolt retract as they slide over the latch fronts and extend into the pockets created by the electric strike’s latches.

The 4800 Series electric strikes operate using one field configurable solenoid and actuator cam that controls the latches and determines the mode of operation.

When configured to Fail Safe mode, the solenoid is continuously powered to lock the two latches keeping the door locked. When power is eliminated, the spring contracts, retracting the solenoid plunger. This movement rotates the Fail Safe actuator cam that depresses the locking collar. With the locking collar depressed, the two latches are free to release the latch or bolt, permitting the door to be open.

When configured to the Fail Secure mode, as the electric strike is momentarily powered, the solenoid plunger retracts into the solenoid body rotating the Fail Secure actuator cam, which in turn depresses the locking collar. When the locking collar is depressed, the two latches are free to swing outward and release the latch or bolt, permitting the door to be open.

The Trine Axion 4800 and 4801 come in one configuration where the built-in electronics automatically allow 12 through 24 volts AC or DC. The 4850 comes in one configuration with the ability to operate the solenoid using 11 through 28VDC. The built-in circuitry is designed to accommodate variations in voltage as well as provide protection against surge and kickback.

These electric strikes are nine inches tall with the opening centered in the body. The strike’s widths are 1-3/4”. The Trine 4800 and 4801 are ¾” thick and the 4850 is ½” thick.

Two mounting holes are horizontal ovals permitting precise inward and outward adjustments. To strengthen the installation of the 4800 Series electric strikes, Trine has patented an anchoring system. Up to four holes are drilled into the jamb at specific locations that correspond to the openings in the electric strike body. Then up to four anchoring system pins are installed into the openings in the strike body. When the electric strike is installed, the anchor pins slide into the jamb. These pins add additional mounting strength to resist lateral pressure.

The 4800 and 4801 come standard with a 1/8” steel spacer that can be used as the mounting template. The 4850 come standard with a 1/8” and ¼” spacers. The rear of the strike box is open in the 4800, 4801 and 4850. Adding one or more spacer(s), moves the electric strike closer to the exit device center case, increasing the acceptable depth for the Pullman Latch or latch bolt throw.

The three electric strikes come with two sealed crimp connectors, quick connect socket and wire assembly and the Fail Safe and Fail Secure spring/solenoid plungers and actuator cams.

For more information, contact your local locksmith wholesaler or:

HES, Inc., 22630 N. 17th Ave., Phoenix, AZ 85027. Telephone: 623-582-4626. Web Site: www.hesinnovations.com.

Rutherford Controls Int’l Corp., 2697 International Parkway, Pkwy 5,Virginia Beach, VA 23452. Telephone: 800-265-6630. Web Site: www.rutherfordcontrols.com.

Trine Access Technology, 1440 Ferris Place, Bronx, NY 10461. Telephone: 718-829-2332. Web Site: www.trineonline.com.