Today’s business customers have developed a strong interest in keyless entry. Whether motivated by need or desire, these customers turn to security providers, installers, contractors and locksmiths to facilitate keyless entry requests.

Keyless entry devices and systems are evolving daily. Locksmiths should be advertising and making attempts to educate the public so that customers will turn to them as their first providers of keyless devices or systems.

This article explains the different steps relating to the “keyless entry” request and how the details the different components and devices relate to the request.

COMPLIANCE MATTERS

Every request for keyless entry will be motivated by compliance or convenience. Requests motivated by compliance occur when the customer is directed to make changes to an existing condition or apply keyless entry to new construction.

Directions can be made by: the local AHJ (authority having jurisdiction), usually the fire marshal or building inspector that has jurisdiction of the business vicinity. These authorities are interested in fire or life safety; conformity to barrier requirements; ingress or egress that affects access for the general public.

In addition, governmental customers have strict requirements relating to the security of doors that lead into storage rooms where classified information is kept. Another example concerns hospitals where strict regulations address the security of rooms and cabinets where drugs are stored.

An example relating to conformance might be where an elevator lobby on a floor of a building allows persons to exit the elevators only to find that doors leading out of the elevator lobby are locked. It is feasible that during a fire, the elevators doors will close and the elevator will (by default) return to the first floor.

In this case the AHJ may require the customer to install fail-safe hardware tied into the fire control system so that when the building goes into fire mode, the power to the hardware is cut, allowing persons caught in the lobby to enter the secured areas and then egress the building from the building refuges (or stairwells).

What type of fail-safe hardware will remedy the situation? How will it tie into the fire control system?

Most elevator lobby doors are reverse-bevel (they swing outward), double doors and fire assemblies. All of these factors complicate what can be used without interfering with other codes and requirements.

Considering matters of compliance, the first priority is how quickly the condition can be rectified.

CONVENIENCE

Customers request keyless entry when it makes their workplace more efficient. This can be as simple as installing an electric strike between the waiting room and exam rooms of a medical office or a pushbutton lock to allow employees to access a protected garage.

Convenience requests are not driven by authorities but any changes to conditions must meet the code requirements set by the authorities.

Locksmiths should always be familiar with local code requirements and know what the AHJ expects. In matters of convenience this may be enough, while in matters of compliance the AHJ usually inspects the changes made.

Considering matters of convenience, the first priority is the return on investment.

Most customers have an idea of what they want, but the results can be disappointing if the expectations are not clearly defined. Unanticipated problems can develop after a keyless entry system is installed.

For instance, after a theft, a business manager might have a lock on a storage room changed out to a simple pushbutton lock. The thinking might be that there were too many keys out, too many suspects and not enough accountability. After the change-out, another theft occurs and now the business manager discovers that everybody is a suspect because anyone could have had the combination.

The locksmith who installed the lock should have explained both pros and cons of pushbutton locks so the business manager would have known what to expect.

Many standalone electronic locks include large groups of personalized numbers and the ability to audit those numbers. These features can determine who comes and goes, and at what time.

By having a locksmith install a keyless device, the customer gains more control over the access. But now the customer must assign the task of managing the new features. Someone will have to administrate the program. The administrator needs to know how to change, enroll, and lock out personal identification numbers.

Locksmiths should take the time to determine what the customer expects and then make recommendations based on those expectations.

Locksmiths new to the process can learn about all the different type of products from several different sources. Lock distributors supply cut sheets, brochure, and catalogs, and often host educational seminars and exhibitions; manufacturer’s representatives are specifically designated to educate locksmiths about the products they represent. Locksmith associations are dedicated to supporting and educating the locksmith. Trade journals provide a wealth of information; and everybody is on the Internet.

AN ELECTRICIAN ON YOUR SIDE

If electricity needs to be brought to transformers, power supplies, and controller boxes, make it so with a licensed electrician.

Develop a working relationship with a certified electrician. The electrician can inspect the electrical service and certify its ability and quality to handle extra loads. The electrician can properly bring electricity to your components and can tie-in the higher voltage to the lower voltage transformer or power supply.

Working with an electrician becomes a natural partnership as the electrician is much more interested in working with alternating current greater than 110 volts, and has much less interest in “electronic” devices that work with lower voltage direct current.

As electricians help locksmiths accomplish these types of requests, locksmiths are in the position to pass requests to electricians they get from their customers, relating to lighting and door annunciators.

A back board is an inexpensive component that streamlines the process of mounting electric boxes and components together in a centralized location. A simple installation (i.e. electric strike, transformer, and pushbutton) will not necessarily call for a back board.

Once the centralized location is chosen (usually a service closet or communication room), a board large enough to have all the components screwed onto it is securely mounted to a wall. Spacing the board away from the wall allows for wires to be hidden (and protected) behind the board.

The back board should be the first component to be mounted as it gives the electrician the exact location where power needs to be provided.

Once the back board is secured to the wall, controller and power supply boxes can be screwed onto it anywhere on its surface. Instruction manuals, logs, and phone numbers can be left on site on a clip board attached to the back board.

An organized back board speaks volumes about the quality of the work performed. It makes it easy for others to follow after the original install, and it makes trouble-shooting simpler.

“CAN” THE TRANSFORMERS & POWER SUPPLIES

Transformers are a type of power supply where standard electricity (110VAC) is converted to a desired lower voltage. The voltage of the transformer is matched to components that require power.

Some transformers are permanently attached to a power outlet. The cover plate is removed and the power supply is then screwed onto the power outlet. Voltage from a transformer is neither regulated nor filtered.

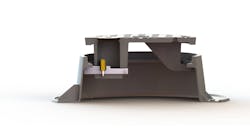

A better way is to place the transformer in a metal box (sometimes called a “can”) large enough for it to dissipate heat. There are cans built for this purpose; they include vents on both sides to dissipate heat.

Power supplies are composed of a power supply circuit board, capacitors, heat sinks, connector strips and a transformer. Power supplies are much more sophisticated as they can regulate, rectify and filter the current. Power supplies are properly fused to protect the more sensitive components that receive power from the supplies.

Electricity supplied to homes and business is unregulated, that is the voltage varies and spikes of electricity can run through power lines. Simple electrical devices in homes and businesses can accept ranges of voltage variance anywhere between 100VAC and 140VAC.

Keyless devices and systems may not be able to handle these variances. Regulated power supplies provide a constant flow of stated voltage. They can filter the voltage to prevent spikes from “frying” components that they feed. Power supplies can also rectify the current; changing the current from alternating current to direct current.

Some power supplies are designed to take into account “loads” or “in rushes.” When some components are first started or several components are turned on at the same time, there is a greater demand for current. Power supplies store energy inside capacitors so that temporarily more energy can be expended to meet the “load” or “in rush.”

Power supplies will vary in quality and the features they provide. Locksmiths should carefully study all specifications when selecting a power supply.

Different components of a keyless system might have different voltages which would require multiple power supplies. For instance, magnetic locks might be rated for 24 volts and the controller might be rated for 12 volts. In this case, two separate power supplies are the prudent way to go.

Some power supplies without a metal box, leaving it up to the locksmith to supply a “can.”

All power supplies and power supply components should always be installed into metal boxes or cans that are large enough for the components to breathe.

What if the power is shut off to the keyless device or system? The doors will unlock or the normal keyless means to enter the doors will not work.

The weakness of batteries in keyless systems is that they don’t work when needed. All batteries fail to hold a charge after a period of time. If not properly monitored or maintained, batteries can be rendered ineffective without notice.

Effectiveness also relies on the selection of batteries. Batteries are rated by amp hours and must be selected based upon the amount of protection time needed. If a system requires 1 amp of constant power, then a battery rated for 1 amp hour will last 60 minutes. It would take two batteries (wired together in series) to provide two hours of power.

CONTROLLERS

An electric strike operated by a receptionist doesn’t need a controller. A button simply interrupts or closes a circuit that provides power to the electric strike.

Systems that require validation of codes, cards, and fobs require a controller. The controller manages transactions by authenticating the credentials it receives and then either sending or shunting power to a locking device. Some controllers maintain a database of transactions that can be accessed by the administrator.

Controllers range in sophistication. Some can control a single circuit while others can control many circuits. Some controllers can send or receive signals from other devices. In high rises, many applications require that controllers be able to receive a signal from the fire control system so that all locks can be defeated while in alarm.

Controllers will range in price based upon sophistication. Locksmiths should always match the controller to the application. It doesn’t make sense to install a controller that can handle multiple circuits when one circuit is needed. It does make sense if there is the possibility of expanding to a second or more circuit in the near future.

Locksmiths should also consider that certain applications require special ratings. The most common rating is UL, especially if attached to other circuits like the fire control system.

Some controllers require a length of time to program. If the locksmith is expected to do this, a provision should cover the amount of time necessary to perform the initial programming.

Who will provide day-to-day programming? If the customer expects to do this, proper documentation must be provided for the customer to “learn” the process.

If the locksmith is going to handle this, what will be the arrangement? Will it be necessary for the customer to provide a remote means for the locksmith to do this? Does programming require the locksmith to visit the site each and every time? All of these requirements must be reviewed with the customer, initially as part of the expectations.

ELECTRIC LOCKING HARDWARE

Each application should be properly matched with the right locking hardware. Where egress is required, electric exit devices must be installed.

Sometimes electric exit devices are used on doors even when there is no requirement to egress, for example storefront (aluminum and glass) doors. Because of the narrow stile of the door, electrified exit devices are much easier to install than “hogging in” an electric strike or running wires to an electrified storefront type deadbolt or latchbolt.

In high use areas, magnetic locks are ideal. Typically, pizza stores will provide magnetic locks tied into exit devices because the doors must reliably lock. The intention is to positively secure the door behind the delivery person so others cannot “piggyback” in. This is to thwart after hours theft.

Today most manufacturers of commercial locksets offer electrified versions. This eliminates the need to retrofit electric strikes.

Current is provided to the lockset. Power is brought to the lock by a conduit mounted to the inside surface of the door, or by way of a concealed raceway inside the door. Surface-mounted conduits have the advantage of not voiding door warranties, boring doors to accept raceways voids the protection rating of the door.

Door manufacturers can provide rated doors with raceways pre-installed.

Fire assemblies; doors and jambs that are rated for fire protection often cannot accept electrified locksets, if concealed raceways are a requirement. Those fire assemblies where the door manufacturers have pre-installed raceways for power must also employ (as part of the fire assembly) electrified hinges that are equally rated.

Electric strikes are a traditional means to facilitate keyless entry. They can require a fair amount of carpentry or metal working. The strike plate and the jamb area the plate is attached to are integral to the security of the lockset. This portion of the jamb is cut out to accommodate the electric strike.

In the process, electric strikes facilitate convenience but degrade the security of the door as strike plates properly mounted to sturdy jambs are stronger than the electric strike.

Electric strikes should only be considered on doors dedicated to traffic control and not the security of a room.

STANDALONE LOCKS

Today’s standalone locks feature batteries that last a long time; the ability to retrofit into existing door preps; the ability to wirelessly receive programming instructions; and the ability to wirelessly transmit access history.

This are electrified locksets that incorporate power, controller assembly, and locking hardware. Additionally, some standalone locks can interface with existing keyless systems.

Standalones are easy to install, and the hardware intentionally complies with existing door preps.

PERIPHERAL INPUT/OUTPUT SENSORS

When configuring keyless systems, there may bells and whistles to install.

An alarm at the top of each door can be added that can be triggered when unauthorized entry is attempted, or a door is propped open.

Lights or buzzers can let persons know when the door is accessible so that the door can be pulled open. The same indicators can be triggered by latch monitors indicating the door isn’t properly latched.

Sensors mounted to the jamb or door can send signals to the controller that a door is opened or closed. These sensors can be tied into other burglary or fire systems (when approved by the AHJ).

KEYED OVERRIDE

Ironically every keyless system should have some type of keyed over-ride. The key should be sparingly distributed. For instance, an electrified lockset or exit device should be keyed in such a way where the locksmith or first responder can make immediate entry, manually. For the fire department the master key that opens these locks should be stored as per their instructions.