Electric strikes were originally invented to allow apartment dwellers to remotely unlock vestibule doors instead of having to trudge down flights of stairs whenever a visitor came to call. Although the power source was electricity, the system was manually operated. A person would physically push a button to release the electric strike.

The majority of those early electric strike mechanisms consisted of an electro-magnet and a spring-operated gate. When current was applied to the electro-magnet, the steel gate was attracted to the electro-magnet and the electric strike was released to an unlocked position. Since the electro-magnets were not very strong, the return spring for resetting the gate to a locked position had to be weak enough to allow the magnetic field to function while having just enough spring strength to return the gate to the locked position once the flow of electricity stopped.

Since the electric source was usually alternating current (AC), the gate flapped back and forth as the current changed every second. The noise from an electric strike caused many people to refer to electric stikes as "buzzers." A byproduct of the buzzing noise was that the life cycle of the thin gate spring was very short. Parts in most electric strikes manufactured two or three decades ago were factory-sealed with no provision for repair. Locksmiths learned to stock quantities of electric strikes because replacement was inevitable, sometimes within months of installation depending on their usage . Fortunately there were only approximately a half- dozen popular electric strike designs at the time, so not many types had to be stocked.

Electric strikes were originally designed to operate in conjunction with spring latches. When the electric strike was locked, it functioned in a way similar to a solid strike plate. The door lock latch would be forced inward as the door was closed. When the door was fully closed, spring action would move the latch into an open area behind the electric strike keeper to secure the door. Whenever the electric strike was electrically actuated, the keeper was free to fold out of the way as a person pulled outwards on the door handle. Once the keeper folded out of the way, the door could be opened even though the latch was not retracted. Most electric strikes require a cutout in the frame in order to allow the extended latch to pass through the frame as the door is opened.

Electric Strikes Vs. Maglocks

Electric strikes have found new life in the last decade. Increased requirements for access control have put the need for electric strikes front and center. The other competing electric locking systems are maglocks and electrified hardware. Maglocks and electrified hardware will operate very well when used in new building construction situations. However, locksmiths are often faced with aftermarket installations where the doors and frames were not originally designed for maglocks or electrified hardware. In a retrofit situation, electrified door locks may require a raceway through the door from hinge to lockset, plus added hardware is needed for connecting the electrical source from jamb to door. Panel doors or doors with panes of glass can present an obstacle to drilling raceways. Battery-operated locks can solve the raceway problem, but do require periodic maintenance for battery replacement.

The optimum location for single point security is midway between the top and bottom of the door. Maglocks are usually installed at the top of the door. When a maglock is mounted at the top of the door, it may allow a tired existing door to flex and not firmly hold the door in a fully closed position. Various local building laws also may not allow a locking system which does not have a mechanical disconnect. A new door and/or frame designed for the specific hardware to be installed is the solution to some of these issues, but this also adds to the cost of the job.

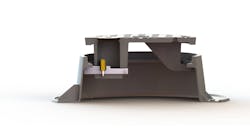

The lowly, one-size-fits-all electric strike from 30 years ago now has new shapes, sizes and options suitable for any situation, and it can usually be easily installed in place of the existing strike with no problem. Electric strikes also help keep installation costs to a minimum by often allowing the owner to continue using their existing doors, frames and door hardware. There are electric strikes with motor-driven gate systems but the majority of electric strikes still consist of an electromagnet source, improved gate locking systems and a keeper.

One of the problems with an aftermarket installation of an electric strike is the latch location of the existing lockset. Mortise lock latch locations vertically on the door can vary by manufacturer. Electric strike manufacturers have solved this problem by making strikes with full-length keepers. Replacement electric strike faceplates are available with cutouts at different height positions on the plate to accommodate almost any latch position.

Another common problem is latches which either bind or have excess in and out play in the electric strike. A feature available on many electric strikes allows you to adjust the horizontal position of the keeper so the door can be easily closed and latched without binding, but will then have only a minimum of in and out door movement. While modern electric strikes are designed to operate even when there is minimal pressure exerted on the keeper, it is always best to eliminate any binding pressure caused by door-to-strike misalignment.

One distinctive feature of most electric strikes is the requirement for a large frame cutout. The cutout can provide an opening for someone to 'knife' the latch to an open position and bypass the electric strike. If the door lock hardware contains a deadlatching function, knifing may not be a big problem. In cases where only a spring latch is providing protection, a guard plate would be a suggested addition.

Several optional items can be added to enhance electric strike performance. If noise is a problem, a rectifier can be added into the low voltage AC power line. A rectifier changes the electrical source from AC to DC which eliminates the buzzing sound. If the originating power is already DC, a piezo horn can be added so a visitor is alerted when the electric strike is released. The low voltage requirement for electric strikes is usually 12 or 24 volts. Phone companies often use 48 volts because it is already available in their buildings for telephone equipment. Some electric strikes must be ordered for a specific voltage while other electric strikes are field-adjustable. Electric strikes can be ordered with monitoring switches which can send a signal when a door is not fully latched. Scar plates for botched installations and extender plates for extra thick door jambs are other available options. At least one company makes a product which includes a proximity card reader and an electric strike all in one unit.

Whenever installing an electric strike in a fire-rated door jamb, check with the Local Authority Having Jurisdiction (LAHJ) to be sure that any enlargement of the door jamb opening which is required for the new electric strike does not violate the fire rating of the door.

A recent variation to appear is the surface-mounted electric strike. These strikes are designed to be only approximately 1/2" thick in order to replace original surface-mounted strike plates on exit devices. Exit devices can now be electrified without mortising and by only drilling a few necessary mounting screw holes. Most of these surface-mounted electric strikes are especially useful for operating pullman-style exit device latches.

For More Information

Following is a partial list of electric strike manufacturers, their web sites and telephone numbers. A more complete listing can be found in Locksmith Ledger’s Online Buyers Guide at http://directory.locksmithledger.com.

Adams-Rite: www.adamsrite.com, 800-872-3267

Folger Adam: www.folgeradamedc.com, 800-626-7590

HES: www.HESinnovations.com, 800-626-7590

Rofu: www.rofu.com, 800-ALL-ROFU

RCI: www.rutherfordcontrols.com, 800-265-6630

Security Door Controls: www.sdcsecurity.com, 800-413-8783

Trine: www.trineonline.com, 718-829-6405

Von Duprin: www.vonduprin.ingersollrand.com, 317-613-8944

To read additional Locksmith Ledger articles about electric strikes, visit http://tinyurl.com/strike1111.

Adams Rite Electric Strike Cross-Reference Chart

Adams Rite Folger Adam HES ROFU RCI Trine Von Duprin

7400, 7100 504,504FS 5000-501A 1702 4104,4304,7104,7304,L6504 2012RD,2012RS 5100,5211AL,6213ALDS

7401,7101 - 5000-501B 1702 - - -

7410,7110 - 5000-502,7000-702,7000-702FS 1404,3404 4108,4308,7108,7308,S6508,L6508 002,002RS,2002,2002WR,EN400 -

7430,7130 505,505FS 5000-503 1403,1703,3403 4107,4307,7107,7307,L6507 2678,2678FS -

7431,7131 - 5000-503B 1703,3403 - - -

7440,7140 502,502S 4500,7000-701,7000-701FS,5000-501 1702,3402 4114,4314,7114,7314,L6514 012,2007,2012,2012RS 6211AL

7160 114-75 1006J,4500,5200-501A,5300,7001 1450 S6504 EN400,EN400RS 5100,6211AL

7170 112-75,652LRF 1006J,1006N,4500,5200-501,5300,7001 1450 2114,4114,S6514 EN400,EN400RS 6211

74R1 262 7000-783S 1960 0161 EN800 6112

74R2 310-4 ½” 7000-789 - - EN850 -

7240* 712/732 1006J 1450 - EN400,EN400RS -

7270* 712/732 1006J 1450 F4114 EN400,EN400RS 6211WF

* UL 10C Fire Rating

No two products are exactly alike, and this cross-reference contains our estimations of other manufacturers’ similar products. The product may differ in design, ANSI/BHMA grade, electrical characteristics, form, fit or function. We accept no liability for misinterpretations.