Dealing with Fire Doors is a critical activity of locksmiths especially when deploying access control. This is because converting the means of how the door locks and unlocks will be changed from a strictly mechanical operation to one which will involve electronic controls and electrical activation.

Fire doors are considered to be assemblies, comprised of several components: the lockset, door closer and electric releasing device included.

The Authority Having Jurisdiction (AHJ) will be very interested in knowing how the new hardware will affect the fire stopping properties of the door, and how the new hardware will affect egress through the door. However, the AHJ will not care at all about how effectively the door will control access into the premises, unless there is a code requirement regarding gaining entry in an emergency. In other words, the AHJ addresses the Life Safety issues and not the Security issues.

Access controlled doors which are along the means of egress are focal points for AHJs. Therefore, getting them right should be your mission as a professional locksmith.

In our age of specialization and misplaced priorities, frequently you will have to deal with integrators who do not understand locks, architects whose main concerns relate to aesthetics, and building owners who seem to care only about costs.

Take also into account that people will be assuming the exits will be operable in an emergency. It is your moral and professional responsibility to do whatever is within you power to assure they are.

A fire door should normally be closed and latched, and it should permit free egress at all times. Although the exceptions to these rules are what make designing access a little interesting and fun, assuring that the rest of the situations where there the exceptions do not apply are the job.

New revisions to NFPA 80 (NFPA 80 2010) will become effective soon, and many jurisdictions will adapt them into their building code. Codes are the Law, and ignorance of the law is not a defense.

If you are dealing with a wood fire door assembly, you might want to consider using an electrified lever. Electrified levers provide an aesthetic solution which provides the same egress capabilities of the original lockset. However they also require wiring of the door.

Drilling through a door without altering its fire rating can be performed by either removing the door and shipping it to a shop authorized to do this, or by someone with Perfect Raceway Certification.

Q&A: Perfect Raceways

Locksmith Ledger contacted Perfect Raceway’s Tom Garrett and asked him the questions about the product you would probably have yourself if you had the opportunity: Following are the Ledger’s questions and Garrett’s answers.

Can you provide an introduction and some background about The Perfect Raceway?

Over the past 20 years, the need for electronic access control and electrified locking hardware has grown exponentially. As a result of this, many fire listed doors and frames have been modified in the field to accept electric locks, electrified strikes and power transfer devices, such as electrified hinges.

Ever since the 1991 edition of the NFPA 80, Standard for Fire Doors, Frames and Other Opening Protectives, was published, the removal of door core and frame material has not been allowed without listing agency field evaluations.

NFPA 80, 2007 Edition calls for the annual inspection of Fire Doors and Frames.

Many doors that were modified in the past will surely be recorded in door inspection field reports, resulting in potential monetary losses to those who modified the doors and those who own the doors.

The Perfect Raceway Program is the first Certified Personnel Program ever designed that allows for technicians to field modify fire listed doors, while still maintaining the door listing status. We say “Be Prepared” for fire door drilling by signing up for this exciting new program.

Do you have any information on what one would charge to modify a door, above

As the training agency for the Perfect Raceway, this question is asked a lot in the classes by the installers. We do not cover installer fees for drilling a raceway in the door.

Does the Perfect Raceway installer typically contract to the end-user, the door supplier or the integrator?

The installer would be able to contract to anyone for their services. Since the installer could be an employee for a building owner, door supplier / integrator or locksmith shop, contracts likely involve any of the entities you mention.

What would be the alternative process to doing a perfect raceway, and how would the expense compare?

An alternative to the personnel certification under the Perfect Raceway Program is to contact the listing agency whose label appears on the fire door and arrange for a field visit to review the raceway field modification. I have heard costs for the listing agency to conduct a field audit can run from $1000 and up depending on how many doors, travel and living costs, travel time for the listing agency personnel, label fees etc.

I see where there is also a list of door inspectors, and for my state (VA), they are not the same entities as on the installer list. How come?

Intertek has two independent programs for the fire door inspectors and the raceway installers. Interested persons can apply to one or both programs.

What is the program to be an inspector, and will this certification and the perfect raceway certification be relevant when NFPA 80 2010 is adapted?

For the Intertek fire door inspector program, the student needs to pass the DHI FDAI class and apply to Intertek to be in the personnel certification program for fire door inspectors. Both programs are relevant to NFPA 80 2010.

Are there alternate programs out there for theses installations/certifications?

Raceway Programs--The Intertek Perfect Raceway Program is the only program of its type to my knowledge at this time.

Fire Door Inspector Program--There are a couple of programs for fire door inspection. The Intertek/DHI program alluded to above and the IFDIA (International Fire Door Inspector Association) accredited curriculum and certification program. Both of these programs are being recognized by the AHJ community.

How can I determine if my perfect raceway will be acceptable to the AHJ, and where more than one AHJ may have jurisdiction, to the AHJs?

Contact the AHJ and provide information on the program. In the three years I have been the training agency for this program, I have not heard of an instance where the Perfect Raceway program was not accepted by the AHJ. Intertek is a nationally recognized listing and testing agency and their programs are accepted by all jurisdictions that I know of. The AHJ can contact Intertek if they have specific questions.

I've heard that the adaptation of NFPA 80, and the 2010 by municipalities may not be timely or unversal, making inspector and Perfect Raceway certifications low priority, and the ROI difficult to project.

Fire Door Inspections are tied into the adoption of the 2009 IFC. The annual fire door inspections are covered in the NFPA 80 2007 edition and a jurisdiction would need to adopt the 2009 IFC to enforce this valuable inspection since this version of the code references the 2007 edition of NFPA 80. Jurisdictions that have adopted a prior year to the 2009 IFC, such as the 2003 or 2006 IFC do not have the annual fire door inspection requirement. Of course jurisdictions can add amendments to their code and require or not require annual fire door inspections.

Perfect Raceway--The Perfect Raceway is an alternative to listing agency field audits to evaluate a raceway drilled into a fire door. The Perfect Raceway would have an immediate ROI for any company that modifies doors and does not wish to engage a listing agency field audit to determine the raceway does not adversely affect the fire rating of the door. There are of course a lot of raceways being installed without listing agency review which in my opinion creates a situation where the fire door rating may be in question and possibly the voiding of the fire door label.

Essential Characteristics of UL1034 Listed Burglary-Resistant Electric Locking Mechanisms

These requirements apply to the construction, performance, and operation of burglary-resistant electric locking mechanisms and their related devices, such as control units, control switches, and power supplies, and the like used to secure and release doors.

Burglary-resistant electric locking mechanisms are rated according to the three elements used to determine its maximum effectiveness:

1- Maximum Static Strength rating of:

- · 500 pounds-force

- · 1000 pounds-force, or

- · 1500 pounds-force

2- Dynamic strength rating of:

- · 33 foot-pounds-force

- · 50 foot-pounds-force, or

- · 70 foot-pounds-force

3- Endurance rating of

- · 100,000 cycles or

- · 250,000 cycles

A UL 1034 burglary-resistant electric locking mechanism is designed to be used in conjunction with an access control system or a manual-release mechanism.

Operation is either that it does not interfere with egress through the door, or its locking action shall be capable of being released as required by the authority having jurisdiction if an emergency egress is required.

Essentials of the UL10C Positive Pressure Fire Tests of Door Assemblies

These methods of fire tests are applicable to swinging door assemblies, including door frames with lights and panels. UL10C does not apply to sliding fire door assemblies), elevator entrance applications.

Locking hardware is considered part of a Fire Door Assembly.

The UL10C test is used evaluate performance during fire tests of specific lengths of time and not how the door assembly will operate after a fire to help determine the suitability of a door for specific sets of requirements. Examples would be for exterior openings in a means of egress in a specific building occupancy group.

The purpose of a fire door is to inhibit the spread of fire and the products of combustion through it. And the tests expose the door assembly to controlled temperatures for the specified time period defined for the particular classification followed by hitting the door with a standard fire hose stream.

UL knows that every fire situation is unique, but the tests have been developed to provide a reasonably accurate means of predicting a door assembly’s performance. UL routinely evaluates fire scenes with respect to how doors have performed in real fires, and adjust their test environments accordingly.

1.5 The tests expose a specimen to a standard fire exposure controlled to achieve specified temperatures throughout a specified time period, followed by the application of a specified standard fire hose stream. The exposure, however, is not representative of all fire conditions, which vary with changes in the amount, nature, and distribution of fire loading, ventilation, compartment size and configuration, and heat sink characteristics of the compartment. It does, however, provide a relative measure of fire performance of door assemblies under these specified fire exposure conditions.

New Electric Strike Choices

Maybe your door requires an electric strike instead. The new HES 8300 & 8500 strikes possess many features which make it a great choice.

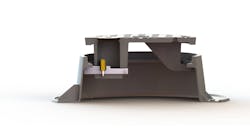

The HES 8500 series is the first concealed electric strike solution for mortise locksets. This electric strike works with 3/4" mortise locksets in either metal or wood frame installations. The 8500 maintains the standard ANSI prep with no cutting into the face of the frame. HES 8500 is available in several finishes and is ANSI/BHMA Grade 1, UL 10C 3-hr fire rated, and UL 1034 burglary resistant listed.

The flexible design of the HES 8500 helps alleviate some of the challenges encountered in the field while working with mortise locksets.

The HES 8300 is a compact, high-performance product for use with cylindrical locksets. The 8300 fits into a standard 1” ANSI/BHMA dustbox, with little or no modification to the frame, and offers vertical adjustability to accommodate door sag and misalignment. Best of all, this electric strike complies with NFPA 80-07 guidelines for retrofit into fire-rated frames.

Tim O'Leary

Tim O'Leary is a security consultant, trainer and technician who has also been writing articles on all areas of locksmithing & physical security for many years.