HES Provides An Integrated Access Control Solution

From my experience, an increasing number of doors are suffering from sagging, settling, poor construction methods, HVAC systems and just plain wear. Also, let’s not forget about east facing heat warpage. And that is sometimes the good news.

Many of these structural problems are continuing and just about any fix can unfix itself over time. Problem doors require creative thinking and solutions to ensure they are able to close and latch. The real problem with doors that do not close and latch easily is they are prime targets for being left open, thereby eliminating any form of access control.

However, in addition to the hammer and adjustment tools, using an electric strike to control access can resolve these problems, providing the building owner is willing to make reasonable repairs, and have periodic inspections and maintenance.

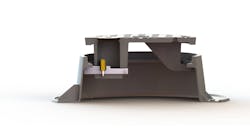

7000 Series

The HES 7000 Series is special among electric strikes having horizontal adjustment and preload handling. Horizontal adjustment allows the electric strike mechanism to move out or in to accommodate the position of the latch. Horizontal adjustment includes movement of the lip to increase the adjustment and installing an optional shim onto the keeper to reduce the adjustment. The 7000 Series preload allows a Fail Secure configured electric strike to release even though latch pressure is being exerted against the keeper. The modular design 7000 Series provides 1/4” horizontal adjustment, with the ability to open electrically under 15 pounds of preload.

This stainless steel construction electric strike keeper is positioned along the centerline of the electric strike body. The 7000 Series operates with cylindrical locks outfitted with up to a 5/8” throw latch and rim exit devices equipped with up to a ¾” throw pivoting style latch.

For cylindrical locks, the 7000 Series electric strike uses the 791 and 792 faceplates meeting ANSI/BHMA A156.31, Grade 1 requirements. The HES 791 faceplate conforms to the ANSI Strike Plate prep. The 792 faceplate is 7-15/16” tall with four mounting holes. For rim and some surface-mounted exit devices equipped with up to a ¾” Pullman style latch, the 7000 Series electric strikes equipped with the 783S, 786S or 789S faceplates meet ANSI/BHMA A156.31, Grade 2 requirements. The electric strike body depth is 1-11/16”.

The 7000 Series is UL 1034, burglary-resistant listed electric strike. The non-handed HES 7000 Series electric strikes have an electrical draw of .45A @ 12VDC and .25A @ 24VDC. The 7000 Series electric strike ships as either 12 or 24VDC and is not field selectable. Both configurations operate with continuous duty solenoids. The operation is field selectable Fail Safe or Fail Secure.

Integrated Prox Products

HES Integrated Prox Products combine an HES electric strike with latchbolt monitor capability with an HID® Prox reader or iClass reader in one package. Twelve electric strike models are available with the integrated Prox HID 125KHz or iClass (smartcard) 13.56MHz card readers. The smartcard reader supports HID iClass credentials, plus CSN read only credentials including MIFARE®, DESFire®, and Sony FeliCa™. Both of the readers interface with Weigand output compatible access control systems. The Prox reader products require 10 to 14VDC and the iClass reader products require 12 to 24VDC. The readers can be located up to 500 feet from the controller.

SMART Pac III

To extend operational life and the warranty, HES offers the SMART Pac III™ in-line power controller. The SMART Pac III provides operational protection for the electric strike and the HES electronics between the power supply and the electric strike. Since most electric strikes are equipped with a solenoid to release or secure the keeper, they can require a significant amount of inrush current to get the solenoid armature and locking/release mechanism moving. Once the armature has moved, less current is required to keep it in the locked/released position.

The SMART Pac III provides the output voltage for two seconds in order to actuate the solenoid to function the electric strike. Then the output voltage is reduced by 25 percent, more than sufficient to keep the armature in position. For a continuous duty solenoid operating a Fail Safe electric strike, this reduced voltage helps to prevent overheating and as a result extends the operational life of the electronics. When being installed with an integrated Prox product, the SMART Pac III is positioned between the power supply and the proximity card reader/ antenna module. The III protects the electronics having built-in surge protection.

When using the HES SMART Pac III, the power supply must provide the correct 12 or 24 input voltage. For example, the HES RF7010 electric strike requires 12VDC input. The SMART Pac III when switched to 12 volts will condition input voltage from 12 volts power supplies that produce from 10.5-21VDC or 10.5-15.5 VAC. The SMART Pac III has a built-in rectifier converting AC input to DC output voltage to a maximum of 15VDC. Once the electric strike has drawn power for two seconds, it will step down the voltage to 9VDC. The output voltage when the SMART Pac III is in the 24 volt configuration is 30VDC maximum with the voltage dropping to 18VDC after two seconds.

The SMART Pac III can detect voltage problems. A built-in LED indicates the status of the input voltage. If the LED is green, the voltage is correct for the electric strike. The LED will indicate if there is a downstream short, or the voltage is incorrect or too high or low. A self-resetting poly switch is built into the SMART Pac III to prevent power surge damage or downstream short.

For this article, I received a RF7010 Integrated Prox electric strike that includes the HES 7000 Series 12VDC electric strike with the latchbolt monitor (LBM). When the latch is within the keeper, the latch depresses the Latchbolt Monitor Actuator Flap (LBMAF). The latchbolt can exit by being retracted or by releasing the keeper, permitting the extended latchbolt to slide out. When the latchbolt exits the keeper, the door is unlocked and can be opened. Once released, the LBM Actuator Flap spring back releasing the switch, sending an open door signal to the controller. When the door is opened, the DPS sends an open door signal to the controller.

I also received the 791 Faceplate Option Kit, an ANSI (4-7/8”) strike plate configuration used on most commercial doorjambs when a cylindrical lock is installed. In the kit were mounting screws and nuts, and shims for the keeper. A trim enhancer is included when the RF7010 is ordered with the 791 or 792 faceplates.

The low profile Prox reader is compact; the visible portion is 1-3/4” tall by 1.25” wide and extends approximately 3/8”. The mortised portion fits into a one-inch diameter opening approximately two inches deep.

In addition to the reader, the Integrated Prox products come with an HES Proximity Card Reader/Antenna (interface) Module, a 3/8” diameter door position magnetic switch (DPS), three wiring pigtails, LBM and DPS wiring and a 24” cable to connect the reader to the interface module. The reader, electric strike and the interface module can be wired into the controller of an access control system using the three provided pigtails.

Note: For the purpose of this article, I machined a piece of aluminum to accommodate the electric strike and the integrated prox components.

The Integrated Prox using the 7000 Series electric strike part number is the RF7010. The part number for the SMART Pac III is 2005M3.

The standard warranty for the HES 7000 Series electric strike is three years, limited. When combined into an integrated product such as the RF7010, the limited warranty against product defect is extended to lifetime.

For more information, contact your local locksmith distributor or HES at Telephone 623.582.4626 Web Site: www.hesinnovations.com