Electromagnetic "mag" locks provide a Fail Safe locking mechanism, which requires power to maintain the holding force. For most applications, they secure a door for the purpose of traffic control. The mag lock is placed either onto or into the doorjamb, usually along the header.

An electromagnetic lock provides its greatest holding force when the door must pull away from the magnet. For a swing type door, the mag lock is placed adjacent to the lock edge of the door, requiring the door face to be pulled directly away. For a sliding door, the mag lock is placed on the locking leg of the doorframe. When the door is closed, the edge contacts the mag lock. To open, the door must be pulled directly away from the magnet.

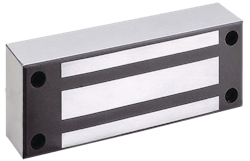

The magnetic portion of the conventional electromagnetic lock is made up of many "E"-shaped thin ferrous metal plates placed adjacent to each other, creating a wide "E". Lying on their back, they form the three metal lines on the face of the magnet. The size and the number of the "E" shaped plates partially determine the holding force of the electromagnetic lock. A copper wire winding creates the magnet field that results from the flow of Direct Current (DC). Electronics are installed to complete the circuitry.

All components are placed into a housing. A non-ferrous potting mixture fills the cavity and encapsulates the components. When the mixture hardens, the surface is machined flat to ensure maximum holding force. Most electromagnetic locks' ferrous metal surfaces are then plated to protect against corrosion and increase durability. Some mag locks have a separate compartment for the wire connections and circuitry.

A ferrous metal strike plate or armature assembly slightly larger than the surface area of the electromagnet completes the locking mechanism. When powered, this spring-loaded plate is drawn flush against the electromagnet. The oversized strike plate provides sufficient surface area if there is settling or wear, protects against tampering and can resist removal of the mounting screws.

For commercial and institutional applications, mag locks are normally 12-24VDC powered electromagnets. The amperage draw ranges from approximately 125mA to more than 500mA at 24VDC, and 230mA to more than 600mA at 12VDC. The magnet size, holding force and construction determine the draw. The low amperage draw makes a simple single-door system capable of being operated by a .5Amp plug-in power supply.

The basic electromagnetic lock designed for a door is available with a holding force ranging from about 400 lbs. to a hybrid model with 4,000 lbs. combined holding force. Construction of the door and the jamb determine the holding force required.

Another electromagnetic lock category is asset management locks, smaller mag locks designed to secure showcases, cabinets, desks, etc. Access for these locks can include keypad/credential readers or remote release, eliminating the need for keys or cards.

Electromagnetic locks have been developed to incorporate just about every configuration of swing and sliding doors, including gates. Mag locks are available for top and side mount applications. They will have mounting holes in the face for rear mount. For top mount electromagnetic locks, there are two options: holes through the body of the magnet or an adjustable mounting bracket.

For double-door applications, two electromagnetic locks can be installed into an aluminum housing, providing a cleaner and more secure installation. A double door example is theCamdenCX-92S-12, which has two 1200-pound surface mount mag locks.

Recessed Mag Lock Applications

Recessed mag lock applications are generally for sliding doors. The recessed application conventional electromagnetic lock can be installed into the locking leg of the doorframe. The Dynalock 2600 Series 650 lbs. holding force mag lock has a narrow backset to accommodate shallow openings. The recessed mag lock contacts the door only when closed.

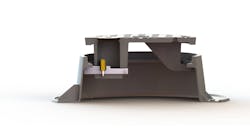

When the recessed mag lock is installed into the header of a sliding door opening, a shear style mag lock is installed. With a conventional magnet in this position, the door slides away from the magnet and the magnetic forces are not strong enough to secure the door. The shear style electromagnetic locks use additional holding force components to keep the door from opening.

An example is a shear lock installed into the header of a sliding door. When closed, the magnet contacts the top of the door. To stop the movement, obstacles interact between the magnetic face and the armature/strike plate. They include ball bearings or steel locking tabs built into the strike plate with receptacles in the lock housing to prevent the door from sliding. When the shear style electromagnetic lock is powered, the strike plate is drawn against the magnetic face and the ball bearings enter into recesses in the face of the magnet or the steel locking tabs enter their recesses. In this condition, the door cannot be slid open.

Shear style electromagnetic locks can have a holding force of 600 to more than 2500 pounds. Shear style electromagnetic locks are sold under different names including Camden Shear Lock, SDC Hi/Shear and Securitron Shear Aligning Magnalock (SAM/SAM2).

Another application for the shear style mag lock is a surface mount application for an inswing door. The SDC 1561TJ Series incorporates a 2,000-pound holding force electromagnetic lock with field-adjustable shear stops. The 1561TJ can be installed onto wood, hollow metal and Herculite style doors with top rails.

The challenge is properly secure the door when the electromagnetic lock is normally positioned along the header for swing door applications. For added protection, some electromagnetic lock manufacturers offer a double mag unit that provides locking near the top and bottom of the swing (lock) side of the door. Other companies offer full length housings where electromagnetic locks are installed.

One such product is the Rofu magnetic door locking device, Model 8122-002, for single-swing door applications. The 83" long bar with two 1,500 -pound electromagnets along each end is a vertically mounted onto the jamb. This device becomes the jamb stop. The Rofu 8122-002 has a door status sensor and is field adjustable 12 or 24VDC.

This type of electromagnetic lock is used in time out rooms or padded rooms of mental institutions, hospital "psych" wards and schools. This type of device eliminates the need of mechanical locks or knobs. It protects the door from major damage by securing it within the jamb. The locking mechanism is operated by a momentary button on the outside of the door. There is a small window in the door for viewing. When pressed, the momentary button provides power. When the button is released, the door can be opened. This way a person cannot be placed in the room and be left unattended.

Delayed Egress Mag Lock

Another electromagnetic lock mechanism that has become more popular is the delayed egress electromagnetic lock. The function of the delayed egress electromagnetic lock is to notify when someone is attempting to exit through a secondary door. Immediately the alarm sounds, notifying employees of an attempted exit. Once activated, the door remains locked for either 15 or 30 seconds depending upon code compliance. After the time delay, the delayed egress mag lock releases and the door can be opened. Delayed egress mag locks are connected to the fire alarm system to automatically unlock in case of a fire.

There are two types of delayed egress electromagnetic locks. One has a built-in sensor that detects when pressure is applied to push open the outswing door. The second type has a special micro-switch equipped non-latching cross bar that is sold with the delayed egress electromagnet. When the bar is pressed, the micro-switch notifies the delayed egress mag lock, sounding the siren as the 15- or 30-second delay time counts down. After the time delay, the delayed egress mag lock releases and the door can be opened.

The free-egress electromagnetic lock has a built-in passive infrared (PIR) sensor that releases the door when someone enters the sensing zone. The Dynalock 3006 Series is a 1500-pound holding force mag lock with the PIR built into the case.

For double-door applications, housings are available that permit two mag locks to be cleanly installed. For aluminum glass doors, a single mag lock can be installed in the center of the opening. Two split strike plates -- one installed onto each leaf of the double doors -- provide sufficient holding force for traffic control.

For single-door applications, Alarm Lock offers the Remote Release Mag-Kit, a 1200-pound electromagnetic lock with an infrared remote release. This kit accommodates up to 100 remotes.

Each manufacturer determines which features are available with what models. Some of the more common features include:

- Voltage sensing that determines the input voltage 12 or 24VDC and configures automatically.

- Door position switch provides notification to the access control system indicating when the door is open or closed.

- Anti-tamper switch or sensor with a wire access chamber which notifies when there is tampering to the chamber cover.

An early warning sensor that detects attempted forced entry, activating a local and/or remote alarm. The patentedRutherfordControls Early Warning Electromagnetic Lock 8310 has a light panel that indicates when the door is secured and notifies with an attempted break-in has occurred.

The Securitron Senstat detects the presence of the armature plate and notifies when the magnet is engaged. The Securitron patented BondSTAT's magnetic field monitors the entire surface of the armature. Any variation in the armatures position beyond established parameters of 95 percent lock voltage present will initiate a signal to the access control or alarm system that the door is not accurately secured.

Relatively new to electromagnetic locks is the integration of a video surveillance camera which captures a facial view of each person exiting the opening. The Securitron M680BDCX Magnalock has an integrated video surveillance camera and passive infrared motion detector.

Some SDC EMLocks, including the Model 1510, feature a modular assembly that enables the electromagnetic lock to be upgraded in the field. Upgrade modules can include Relock Delay Timer, Magnetic Bond Sensor, Door Status Sensors, Anti-Tamper Switch, Holding Force Upgrade and Energy Saver Upgrade.

The advantages of electromagnetic locks are no moving parts, little or no maintenance and the lock requires little power to operate.

Because the electromagnetic lock is Fail Safe, unlocking when power is removed, the mag lock should not be the primary locking mechanism in many applications.

Instant circuit release eliminates the problem that occurs with residual magnetism on older mag locks. Residual magnetism can build up in an electromagnet. The ferrous metal portion becomes magnetized. Over time the strength of the magnet increases. This can be felt when there is resistance when trying to open the door when the mag lock is not powered. This can eventually result in the door being difficult to open. Most newer mag locks include a release circuit that eliminates residual magnetism.

Gate electromagnetic locks normally have fittings to run the wiring through electrical conduit in order to protect against tampering and armatures with shock absorbing mounts. Seco-Larm’s electromagnetic gate locks are water and vandal resistant. Some gate mag locks have weldable brackets for the armature and the magnet. BEA and RCI gate mag locks have stainless steel housings.

Electromagnetic locks can be installed nearly any type of door or gate, using mounting brackets and accessories when needed.

Brackets are designed for most door applications and configurations including specialized "Z" brackets used to install a mag lock onto an inswing door. There are brackets for installing an electromagnetic lock onto glass doors.

Mounting brackets are available to surface-mount mag locks. There are filler plates, header brackets, shims and concrete and wood brackets. Dress covers enable mag locks to be color coordinated to the surroundings.

When installing an electromagnetic lock, it is recommended that thread lock be applied to all screws to reduce the possibility of screws loosening over the life of the device.

When installing the unit onto a wood jamb, follow the manufacturer’s fastener recommendations. When installed the lock onto a hollow metal or aluminum jambs, the use of blind nuts is strongly recommended for most doors and doorframes to insure a secure installation.

Electromagnetic lock warranties range from one year to lifetime replacement and they can vary by manufacturer and model.

Important: Make certain the installation will follow all building, life safety and electrical codes, and laws including the ADA and local regulations for the area. Contact your local authority having jurisdiction before purchasing and installing the lock.

For More Information

The following is a partial list of electromechanical lock manufacturers and their web sites.

Alarm Lock: www.alarmlock.com

BEA: www.beainc.com

Camden: www.camdencontrols.com

DORMA: www.dorma.com/us

Dortronics: www.dortronics.com

DynaLock: www.dynalock.com

RCI: www.rutherfordcontrols.com

Rofu: www.Rofu.com

Schlage: www.Schlage.com

SDC: www.sdcsecurity.com

Seco-Larm: www.seco-larm.com

Securitron: www.Securitron.com

For a more complete list, see the Locksmith Ledger Online Buyers Guide, www.locksmithledger.com/directory.