Installing the HES ES100

The advantages of using wireless products for door and entrance controls are clear: time and labor savings, fewer hard-wired components and the ability to complete more projects in a shorter time span, thus boosting job profitability. Wireless strikes are the latest component that can help security pros take advantage of reliable wireless signaling to extend traditional door specifications into electronic access control (EAC).

As end users continue to move to EAC for additional security at doors and locations throughout their facilities, dealing with infrastructure constraints is an ongoing issue. Wireless EAC products are excellent retrofit option to add access control while using existing locksets. There’s no need to drill the door; no power transfer device is necessary; and monitored and nonmonitored options are available.

A Wireless Strike

The HES ES100 Aperio Wireless Integrated Electric Strike and Card Reader, introduced in spring 2021, comes in two options. It’s available as a kit, where the factory takes the guesswork out of connecting the lock to a Wiegand 1-to-1 network hub, which provides basic functionality. No Aperio certification is required for this product. The ES100 also can be individual, field-configurable components for more-advanced, customized installations, which would require certification.

Electric strikes are relatively simple to install because they generally take the place of an existing strike. If this isn’t the case for your installation, you might have to prepare and cut the frame to work with either cylindrical or mortise locksets, with or without a deadbolt.

Mounting options for the ES100 reader include drywall, glass, stone, concrete, brick, hollow metal, aluminum or prefinished steel door frames. In other words, just about everything is possible.

Two locksmiths shared insights after recently installing the ES100. Joe Small is the lead technician for A&B Security in Las Vegas. Tony Dahlin is the owner of Bullis Systems in Chicago, which has served the Chicagoland area since 1920.

Campus Facility

Small installed the wireless strike for a higher education facility, initially on a single door to test the product.

“The application is a glass door, and you can’t run wires [to it] because of the door headers in the glass, so the wireless strike was the perfect fit,” Small says.

Preparing the worksite was the first step, with the correct tools at the ready and protective coverings to keep the workspace clean. Small says he used the HES Template Kit and selected the proper size template for the door frame to help with the installation.

“You draw that out, measure it twice and use a jigsaw to cut out the measurement marked on the frame,” he says. “I used a 3/8-inch bit to drill into the frame and cut out for the strike. After that’s done, we terminated the wires from the strike to the reader’s power and data cables.”

The ES100 also can be installed by using an included trim piece enhancer that serves as a guide to cut the frame.

Small says he tested the wireless signal strength. It’s specified for 75 feet but in this case tested as far as 100 feet. He adds that the reader indicates a light when the battery is low, and a USB hookup on the side of the reader allows you to install a battery pack if necessary. Because the ES100 is fail-secure, the door will latch closed during a power outage.

“We really put it through the paces in testing,” Small says. “We scanned the reader over and over to see how fast the reader communicates with the strike at the opening for throughput, and there was minimal latency. We have it connected to the hub and a web-based interface, which allows us to see in all the transactions and activity in real time.”

As far as the components, Small says the reader has a somewhat larger footprint, but that’s because it houses more components. He says that from start to clean up, the installation took about two hours.

“The strike installation was completed in about one hour, and then there was another hour for final termination, testing and cleanup,” he explains. In addition to labor savings, Small says there’s significant savings on conduit and wire, which have had exponential cost increases.

Commercial Office Space

Dahlin installed the ES100 at the headquarters of a large nonprofit that has two entrances. Both areas are difficult to establish a hard-wired wire run.

In this first-time installation, Dahlin says he had to install the wireless strike and reader inside a brick vestibule, an area that was added after construction.

“It would be labor-intensive to run the wire and drill through the brick,” he notes. “The wireless strike gave us the opportunity to install access control cleanly, with no surface cabling.” Dahlin says the installation was no different than any electric strike other than the fact that the reader provides the latching power from two AA batteries.

“To install the wireless strike and for a typical installation, the parameters depend on the type of door or the frame to determine the tool,” he says. “On an aluminum storefront [door], we used a router and a jigsaw to cut into the frame. We used a rotary tool on a traditional door. The tools you need [for a wireless strike] will be ones you already have.”

Dahlin connected the electric strike to the reader’s main power cable and tucked the excess wire carefully into the frame before mounting. He secured the strike body and faceplate to the frame by using the provided mounting hardware, checked the latch engagement and adjusted the shim accordingly.

“Once the strike body and faceplate were installed and secured, I connected the electric strike to the reader’s main power cable and to the reader, ensuring a proper distance between the strike and the reader wire without straining the cables and connection,” Dahlin says. “I used a wire or fish tape to pull the ES100 reader’s power and data cable into the strike pocket. We commissioned the reader through the hub and the access control head-end management platform, which has an integration with Aperio.”

With the ES100 installed and the communication hub connected, Dahlin tested its functionality with access credentials. When a valid credential was presented to the ES100 reader, the green LED illuminated and the strike released. When an invalid credential was presented, the red LED illuminated and access was denied.

Dahlin says he installed the wireless strike in just under one hour but adds that he usually quotes an hour and a half to terminate wiring, test the product and link it to the hub.

“We can save about one-third of the time installing wireless versus hardwired access control, driving down the cost per door,” he says. “What’s scary or may be outside the budget of the client now becomes attractive. It’s easier to install, easier to quote, and there are no surprises or hidden costs.”

Ruben Salazar is the technical support manager for ASSA ABLOY Electromechanical Solutions Group.

To watch a video of the installation, go to https://www.assaabloyesh.com/en/training/onlinetraining/

Tools for the Task

- Included tools: 5/64-inch hex wrench, Torx T8 Driver Security Bit and alcohol swab to clean the surface when mounting the reader.

- General installation tools necessary: a tape measure, bubble level, electric drill, 3/8-inch drill bit, 5/8-inch drill bit, Phillips drill bit or manual screwdriver, center punch and a pencil or other marker.

- For strike cut-in: high-speed rotary tool, metal file, needle-nose pliers and fish tape.

- Optional: HESCUT-MTK Metal Template Kit and painter’s tape.

Making the Installation

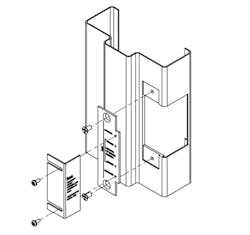

The images show part of the installation procedure, including cutting the frame for the strike (Image 1), running the wire that will connect the reader and strike (Image 2), attaching the reader (Image 3), connecting the strike (Image 4) and attaching the faceplate on the strike. To watch a video of the installation, go to https://www.assaabloyesh.com/en/training/onlinetraining/

Further Notes

- The ES100 is a fail-secure electric strike. If batteries get close to depletion, the final amount of energy will be used to push the strike into a locked state. Batteries last about 45,000 cycles.

- The ES100 electric strike body and card readers are uniquely paired to work only with each other at the factory through AES 256-bit encryption.

- When the reader is mounted using screws, a room-temperature-vulcanizing silicone or similar sealant should be used to prevent moisture and debris from entering the reader through the mounting holes.

Ruben Salazar

Ruben Salazar is Director of Customer Care for ASSA ABLOY’s Electromechanical Solutions Group in Phoenix, AZ, leading Customer Service, Tech Support and Product Training departments for HES, Adams Rite, Securitron and Alarm Controls.