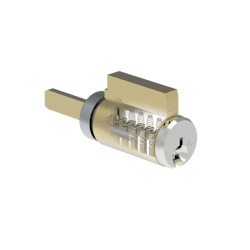

In this world of new electronic security products, Schlage has introduced an interesting new mechanical cylinder. Known as the Everest SL cylinder, it has seven tumblers and uses popular A2 depth and spacing. The SL cylinder is not IC core removal, but is basically designed to retrofit six-pin cylinders in existing Schlage knob or lever locks. The best example would be when a building using a Schlage Everest LFIC core key system and a building which has existing Schlage six-pin locks need to have the same master key system. Using new Everest SL cylinders, the existing six-pin cylinders can be replaced without an added expense of completely replacing existing knob or lever lock hardware.

In order to fit seven tumblers into the space originally made for six tumblers, Schlage engineers changed from round to flat tumblers. New tumblers are known as L-Pins because of their 'L' shape. If readers are familiar with the single sided 6-cut key system used for many years by GM, then they will understand the locking principle used in Schlage Everest SL cylinders.

Cylinder locking is accomplished with a sidebar. Each 'L' tumbler has at least one cutaway notch in the side of the tumbler. If notches in all seven tumblers are aligned correctly by an operating key, then an opening is provided for the sidebar. The sidebar and locking groove in the housing are both slightly 'U' shaped. As the correct key begins to be rotated, interaction between the sidebar and the housing causes the spring-loaded sidebar to move inward and the plug can continue to be rotated for locking or unlocking.

As noted in the last paragraph, each 'L' tumbler has at least one notch corresponding to the depth of cut on the operating key. In cases where the Everest SL cylinder must be keyed into a master key system, two notches are cut into the 'L' tumbler. As example, if a master key has a cut depth of "0" and the change key has a cut depth of "4," then a tumbler with notches for 0 & 4 are cut into the 'L' tumbler.

Schlage offers a total of 20 double-cut tumblers, one for every even cut or odd cut situation normally used when combinating A2 key systems. Ten single-cut tumblers are also available covering cut depths of 0-9. Cylinder keying cannot be simpler. No adding or subtracting is necessary when combinating a Schlage Everest SL cylinder. Locksmiths must only know what two cuts are used in a given space and no consideration is required as to which cut is shallow and which cut is deep.

'L' tumblers are not completely flat. A rounded section in each tumbler contains a hollow area for containing the tumbler spring. A 'U' shaped spring cap is pressed flat to hold the springs in place. All moving parts are contained within the cylinder plug. The normal driver pin and spring area (often called a bible) is completely solid and only serves to fit into the cutout in existing locksets to prevent unwanted rotation of the complete Everest SL housing unit.

An additional locking feature is provided by an Everest blocking pin which is moved out its locked position as an operating Everest key is inserted into the lock plug. Schlage literature states, "The Everest 29 SL and Everest 29 SL w/Primus XP cylinders fit into Schlage KIL/KIK, mortise and rim modular cylinders as well as an extensive list of competitors' cylindrical locks."

Everest side bitting is cut into the key blanks at the factory. Keys can be duplicated or originated in the field using standard key cutting equipment.

A revised tailpiece system is used with Everest SL cylinders. The lock plug is held in the housing with a 'C' shaped retainer. Ends of cylinder plugs contain a groove instead of previously used threads. The tailpiece is retained on the lock plug by one quarter turn of the cylinder cap. A spring and pin, similar to the standard threaded cap retaining system, prevents the non-threaded cylinder cap from being removed. Everest SL cylinders can also be used in Schlage modular cylinder housings. Special mortise lock cams can be rotated into a vertical position. A similar spring and pin system then holds the cam in an upright position.

Three special tools are available for servicing Everest SL locks. Tools consist of a capping tool for assembling SL lock cylinders, a key gauge for reading cut depths and a decoding tool for determining the depth value of unknown SL tumblers. To deter possible surreptitious identification methods, Everest SL tumblers have no markings or color coding of any kind.

Generation of Everest SL masterkey systems is no different than developing any other A2 key system except that there is no control key pinning. Depths are: 0).3187 1).3062 2).2937 3) .2812 4).2687 5).2562 6).2437 7).2312 8).2187 9).2062.

Spacing is measured from the shoulder: 1).196 2).346 3).496 4).646 5).796 6).946 7).1096.

HPC code machines use card C116.

For more information contact your local locksmith distributor or: Allegion at: www.allegion.com