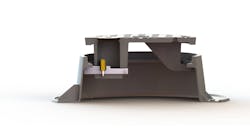

Some time in the 1950s Mosler made a file safe which contained a normal combination lock and an individual locking handle. The safe door moved in a track and could be opened and then pushed out of sight into an enclosed pocket on the side of the safe cabinet. The handle, often called a butterfly handle because of its shape, sits flush with the door face to allow full door movement into the enclosed pocket. A locksmith was called to fit keys to a Mosler butterfly handle and called our office for assistance when he could not do the job. We accepted the key fitting challenge.

Numbers printed on the face of the lock handle were originally thought to be key codes. The lock plug was positively identified as having a K4R double-sided keyway by Chicago Lock. Chicago Lock is part of the CompX company and a call was made to CompX in hopes of obtaining the correct "H" series cross-reference code but CompX had no code records for this Mosler lock handle. Some other method would be required to fit the keys.

The basic Chicago Lock double-sided code series is H2001-H2576. There are only 576 possible cut shapes used for Chicago double-sided locks. While there are many Chicago Lock code series, every code in those series uses one of these original 576 shapes. When the Chicago Lock double-sided key system was invented, they began with 24 basic shapes.

SPACING: There are 11 wafer tumblers in a Chicago lock plug. Each Chicago key has a wide enough cut area on each side of the key to operate more than 11 wafers ‑ similar to a 7-cut Schlage key operating a 5-cut Schlage lock. This allows the same cut shape to be moved towards the tip of the key and still have enough cuts to operate 11 tumblers. Spacing from the shoulder to the first cut on each basic shape can be moved four times in approximately .045" increments, which provides 4 times the 24 original shapes, or 96 total key shapes. Our chart shows the "A" measurement relationship between the four variations in spacing from shoulder to the beginning of the first vertical key cut.

DEPTHS: There are three possible sets of depths used by Chicago Lock double-sided keys. For simplicity, these can be called left (L), center (C) and right (R). By moving the original 24 shapes approximately .015 to the left of center, or .015 to the right of center, each of the original 24 shapes can be used three different ways. This provided 96 times 3, or 288 different key shapes which can be developed from the original 24 shapes. The chart also shows the relationship between L, C and R key shapes and "A" dimensioning.

REVERSED SHAPES: Finally, each of the 288 key shapes can be flipped over so the left side cuts are on the right and right side cuts are on the left. Chicago double-sided keys are not bi-directional so they can only be inserted one direction. This provides two uses for each of the 288 key shapes producing two times 288 or 576 total key shapes. The chart shows the complete set of 288 key code numbers. Add '6' to any key code and you will have the exact opposite of that key shape. As example: Add '6' to Key H2361 (2367). Key H2367 is the mirror reverse of H2361.

KEYWAYS: Since there are only 576 key shapes, Chicago Lock invented more keyways to extend the amount of key changes. The most popular keyways are K4, K4R, K4L and K4W. More exotic keyways were used for special applications such as pop machines but every key cut is one of the original 576 cut shapes. Only the keyways are different.

Sets of 402 precut Chicago double-sided keys are available from locksmith distributors. CompX lists the part number as D9402. For unknown reasons, 174 guide keys out of the 576 possible precut keys are not included in the CompX D9402 guide key set. Aftermarket companies offer smaller groups of tryout keys for Chicago double-sided locks. For purposes of this article the CompX D9402 guide key set is recommended. Duplicates of aftermarket tryout keys either may not operate easily or may be able to be removed when the plug is only partially turned.

The first procedure involved removal of the lock plug from the butterfly housing. A retaining pin was located on the side of the handle. The pin had been permanently pressed into place so the only alternative was to drill the retaining pin out. Once the retaining pin was drilled out, the lock plug could be removed from the butterfly handle.

Now that we know how the Chicago Lock shape system operates, it becomes easier to determine the key code for the Mosler butterfly handle. However, to test whether we have chosen the correct key shape, guide keys must be inserted into the lock plug. Since our lock plug uses the K4R keyway, it is impossible to insert guide keys from the D9402 set since they are precut on K4 key blanks.

The next step was to remove the nest of tumblers from the Mosler lock plug and place the tumblers in the same order into a nest having the K4 keyway. The K4 nest was then inserted into a surrogate K4 plug so the guide keys could be inserted and tested. It was certainly possible to replace the old Mosler tumbler nest with one which already had operating keys but in this case we wanted to determine the exact key code for this particular Mosler lock in case the Mosler question ever comes up again. We still believe that the numbers stamped on the handle were Mosler key codes but since Mosler is out of business, there is no way of knowing.

Chicago key blades are approximately .400” wide. Windows in the 11 wafer tumblers are approximately .190” wide. Keys for Chicago double-sided locks must be cut before the key blade will enter through the tumbler windows. A trial key was made by cutting approximately .105" from each side of a K4 key blank. The trial key blade was then approximately .190" wide and could be inserted into the lock. The trial key then held the tumblers in the same general shape as the key cuts on an operating key.

The shape of the tumblers when held by the trial key was then compared to the shape of the 24 original key shapes. In this case key shape 9 had a very similar configuration. The second guide key tried, H2183, was an exact match for the key cuts.

An alternate method would have been to use key numbers listed in the "C" column under the A =.057 groupings. 24 keys could have been tried, one from each key shape group in column "C". Each key could have been retracted slightly to test key cuts at the .057, .100, .142 and .185 space dimensions. Once a straight wafer alignment is discovered, L and R keys from that "A" group could have been tried to adjust tumbler height to the perfect shearline.

The next step was to transfer the cuts from the H2183 key to a K4R blank. This reporter had access to an ancient Sagar duplicating machine designed to cut double-sided keys. Keys are retained in the Sagar machine with a vise jaw which holds into the center key groove. However, the grooves in the k4 blank and the K4R blank are not at the same center position. Guides on the Sagar machine were then offset to compensate for the groove position difference which solved the problem.

Final steps in the key fitting procedure consisted of replacing the 11 tumblers back into the original K4R nest. A replacement pin was turned on a lathe and pressed into position to retain the plug in the butterfly housing.

A majority of Chicago locks using double-sided keyways have the key code printed on the housing. If no code number is present, and the keyway is K4, it is a simply matter of time to use a set of tryout keys. This procedure can be helpful when If the keyway is not a K4 / CG1 keyway, when there is no usable key code available, and when the plug can be removed for servicing.