Mercedes introduced a new type of key 30 years ago which came to be known as a sidewinder. Key cuts were not made completely through the blade as with previous automotive keys. Instead, each key cut was milled onto the surface of the blank. This required a new type of key making machine with similarities to a stationary router. This new key system was at first limited to Mercedes and BMW vehicles. During the last 10 years almost every major car manufacturer except Mitsubishi has joined the sidewinder key revolution.

Every sidewinder key system has its own peculiarities, such as differences in depths, spaces and tip or shoulder stop positioning. Sidewinder keys can basically be divided into two types which either have internal cuts down the center of the blank or have external cuts along the edge of the blank. In addition, sidewinder keys can be either 2-track keys with tumbler spring pressure pressing against one side of the blade, or the keys can be 4-track keys with tumbler spring pressure usually alternating left to right from tumbler to tumbler. Sidewinder keys contain identical cuts on each side of the key which allows the key to be inserted without regard for key orientation.

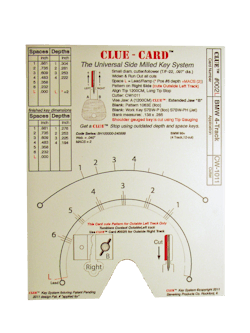

Until now, the only method for sidewinder key origination was either by the tedious process of using depth and space keys or with an expensive electronic code machine. Sieveking Products Co. has recently introduced a new Clue-Card TM program which is a less expensive way to originate many types of automotive sidewinder keys. The Clue-Card system requires the use of both a card-type code machine and a manual sidewinder machine.

The Clue-Card system assumes that you already know what key cuts are needed. This requires either knowing the key code, disassembling a lock, or by using aftermarket sidewinder picks to decode the cuts.

The first procedure is to make a pattern key. One or two Clue-Cards will be needed depending on whether the key is a 2-track or 4-track type. Sieveking recommends the use of two different safe deposit key blanks, Ilco 1063E or 1323L, either of which can be used to make pattern keys. All pattern keys are tip-stopped in the card-type code machine. The normal extended tip on safe deposit box key blanks must be removed to make a straight, smooth end on the blank.

Before inserting a card into the machine, read the informational notes in the Sieveking operators manual and on the Clue-Card used for the specific key type being originated. Vise jaw A and cutter CW-1011 are currently required for all Clue-Card procedures.

To make a pattern key, the safe deposit blank must be tip stopped against the inner or outer vise jaw stop of the card type code machine as indicated in the Sieveking instructions. Secondary space lines are included on each card. The secondary marks are used to slightly widen the cuts and also to remove the peaks between each cut. This then produces smooth, laser-like cuts on the pattern key. Sieveking also includes instructions on how to complete the tip of each pattern key to make the correctly positioned lead area ramp angle.

A Clue fixture is also included with the system. This fixture is designed to be clamped into the jaw of a manual sidewinder duplicator (where an original key would normally be inserted). The fixture is double-sided, allowing a pattern key to be installed on the left or right side of the fixture as needed. Two jaws, A & B, are included. Sieveking A & B jaws operate in a similar manner to standard A & B jaws for a card type code machine. The B jaw holds the pattern key closer to the center line of a sidewinder blank while the A jaw holds the pattern key farther away from the center line of a sidewinder key. The combination of using either A or B jaws according to instructions in the manual plus carefully calibrated Clue Cards will produce keys within .001 to .003 of a manufacturers listed dimensions according to Sieveking Products Co.

Two different sizes of cutter blades are required. Most sidewinder keys can be originated by using a .097" diameter cutter, but a few keys will require a cutter diameter of .118. Each Clue-Card contains information for which cutter diameter to use.

Cutter height is the final adjustment to be made before originating a sidewinder key. During key cutting, material is removed from both sides of the key blank. A center portion of the key blank remains in order to provide strength and rigidity to the finished key. This center portion is called the 'web'. Depending on the key blank shape and size, the web thickness dimension can vary from .025 to .040. If the web is too thick, the key either cannot be inserted or the tumblers can become deformed if the key is forced into the lock. If the web is too thin, the key blank will be more easily broken or bent during use.

The Sieveking manual suggests two methods for setting the cutter height. First, any original key from the same code series can be used to set the cutter depth. A second method is to make a step gauge key which contains steps wi9th the correct thickness. Thicknesses can be mathematically determined from measurements provided on each Clue-Card. The Sieveking manual states that only four different depths (steps) are required in a gauge key he uses.

Once the cutter height is complete, the contour from the pattern key or keys is duplicated onto the proper sidewinder key blank. When ordering a Clue-Card system, you must indicate the manufacturer of the sidewinder duplicator you are using. Vise jaw movement depending on which key machine you have. Different Clue fixture dimensioning is needed to compensate for the vise jaw designs.

Sidewinder key systems have taken over the automotive market. It order to 'stay in the game' it is necessary to be prepared to service these type of keys. The Sieveking Clue-Card system provides a simple answer to sidewinder key originating at an economical cost.