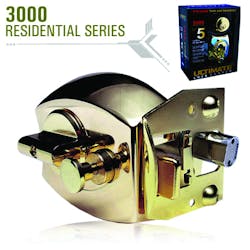

The Ultimate Lock Solution

When someone uses the word ultimate, it indicates a certain finality with no possibility of finding something in that category that solves the problem better. Ron Daniels, a law enforcement officer in Texas, saw the need for a better locking system than was currently available and set out to develop The Ultimate Lock System. This was no easy task. Mr. Daniels discovered that present door locks do not fully utilize the strongest structural part of a door system, the door frame.

We have all either seen pictures or been called to a job where a door has been forced open. In most cases, a weak section of the door adjacent to the deadbolt unit fractures, the deadbolt is no longer held securely in place and the door can be opened.

To combat this problem the 3000 series residential Ultimate Lock has two major parts, a mortise deadbolt and a rim deadbolt. If there is an existing cylindrical deadbolt on the door, it is removed and replaced with the new Ultimate deadbolt lock unit. Once the cylindrical deadbolt is installed, a second, rim deadbolt housing is installed on the inner surface of the door. The completed installation couples the rim and cylindrical deadbolts together so that with either a turn of the inner knob or a turn of the key in the outer cylinder, both mortise and rim deadbolts are simultaneously retracted or extended as needed.

A second feature of The Ultimate Lock is the strike plate. The strike plate contains two cutout holes, one for the cylindrical deadbolt and one for the rim deadbolt. Four screws firmly anchor the strike plate to the door jamb. Two 3/4” screws are inserted at right angles, connecting the strike plate to the finished door jamb. Two additional screws anchor the strike plate directly to the wall studs. The screws are approximately 3 1/2” long and are inserted through the strike plate on a 45 degree angle to provide a greater holding strength against inward pressure during a forced entry attempt.

INSTALLATION

Cutouts for the cylindrical deadbolt include a standard 2 1/8” hole drilled through the door and a 1” hole drilled on the edge of the door. The deadbolt can be fastened in place, but the outer cylinder is not installed at this time.

The next major part to be installed is the platform. Two screws are inserted through the platform to retain the outer lock cylinder. A geared shaft is also installed into the platform. The geared shaft forms a connection between the outer lock cylinder, the cylindrical deadbolt and the rim lock bolt. A second channel section is then inserted on top of the platform. This channel section holds the rim lock bolt in position.

Six screws are inserted through the channel and platform sections to fasten the rim unit parts onto the door. These screws are fastened into solid door material above and below the one inch hole drilled for the cylindrical deadbolt. In my opinion, this is one of the real secrets of the Ultimate Lock system. The platform and channel sections spread the holding strength over a large area. This prevents the

thin sections adjacent to the cylindrical deadbolt from taking the full brunt of a forced entry attack.

Lastly, a decorative trim cover is installed over the platform and channel parts. This trim houses the inner thumb turn and a lock-out button. When the Ultimate Lock is in a locked position, the lock-out button can be positioned to prevent both deadbolts from retracting. Even if the outer cylinder could be ‘bumped’ or picked open, the cylinder is prevented from turning far enough to unlock the door.

FEATURES

Ultimate Lock literature lists the following features:

• Withstands up to 4000 lbs. of force

• Special engineered steel strike plate

• Super hardened steel security bar

• Patented lock-out feature

• High security 6-pin anti-bump keylock

The Ultimate Lock website, www.ultimatelock.net, shows police officers using battering tools and leg power in an effort to force open doors fitted with the Ultimate Lock. It is quite impressive to watch. For further information, contact Ultimate Lock at: 866-657-4005.