Early in the 20th century an inventor in Finland studied the pin tumbler locking system and decided to find a better way. At that moment the Abloy disc locking principle was born and it has competed well in the security field for over 90 years. The Abloy locking system consists of a series of discs, each with a cutout notch which can be located at different positions around the outer surface of the disc. A rounded locking bar is located in between a groove in the housing and a groove in the plug to block the plug from turning.

The present version of the Abloy disc system is called Protec. The center of each disc is cut out to accept a Protec key blank. Surfaces on the Protec key blank are cut away at various angles. When a Protec key is inserted fully into the lock and turned 90 degrees, each disc is partially rotated according to the angled cuts made on the key. If the correct operating Abloy key has been inserted, all of the notches in the discs will be aligned under the locking bar. Continued turning of the Protec key moves the rounded locking bar into the groove formed by the notches in the discs and out of the locking groove in the housing. The plug is now free to be revolved further to complete either the locking or unlocking procedure.

The Abloy Protec lock cylinder design provides many advantageous features. Nine operating discs allow for the development of extensive master key systems. According to Abloy, there are over 1.97 billion possible key combinations per keyway available. Protec keys do not engage the discs until the key is fully inserted. This provides for smooth key insertion or removal and reduces the wear factor associated with spring-driven pin tumbler systems. Discs are directly moved into position as the user turns the key. Therefore Protec lock cylinder operation is less affected by harsh weather conditions. Finally, Abloy literature states that their Protec lock has a virtually pickproof design.

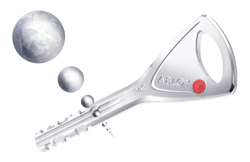

A new Abloy Protec 2 lock system will be introduced at the ALOA convention in July. This design features a new disc controller and provides patent protection until the year 2031. This new design incorporates a captured, floating ball in the key blank. A locking pin plus three spring-loaded ball bearings are located in the disc controller. When no key is present in the lock, the disc controller is held in position by the locking pin and will not rotate. This is an added feature to deter any attempt at lock picking.

After the proper Protec 2 key is fully inserted into the cylinder, one of the spring-loaded ball bearings in the controller engages the floating ball bearing in the key blank. The controller ball bearing, the ball bearing in the key blank and the locking pin then become interconnected, forming a solid column. As the user begins rotating the Protec 2 key, the locking pin is moved to a released position by the solid column, allowing the proper Abloy Protec 2 key to correctly align the Abloy discs during the first 90-degree rotation. The Protec 2 key can then be fully turned to complete a required locking or unlocking procedure.

Another important advantage of the Abloy Protec and Protec 2 disc principle is that no extra chamber area is required to contain pin tumbler driver pins and springs. This allows the compact Abloy disc system to be installed in every popular type of lock product. Abloy Protec locks are available in a full range of products including cabinet locks, vending locks, maximum security padlocks, electric switches and cam locks. Popular commercial applications such as deadbolts, mortise cylinders, rim cylinders plus all popular key-in-knob and lever handle cylinders complete the Abloy Protec lineup. Most importantly, all of these lock types can be keyed alike together as needed or included in a master key system of any size or requirement.

Abloy Protec lock cylinders are also available in an electromechanical form called CLIQ. Electronic components are encased within the cylinder housing. Existing locking hardware can be re-used; only the lock cylinder must be replaced. Abloy CLIQ cylinders combine the security of the Protec disc system with the convenient flexibility of electronic management. Batteryless, patented and encrypted electronic components in the Abloy Protec lock cylinder control time zones and individual access, while maintaining an audit trail. All programming can be handled by a programming device and computer software. Programming keys are used to carry programming information from the programming device to the lock cylinders. A web-based version of the CLIQ program is also available.

Abloy is building a network of both locksmith dealerships and Abloy locksmith distributors across the country. A Texas Abloy warehouse opened in 2011 with a full staff geared to quickly deliver products. The Texas facility also has automated key cutting equipment for speedy deliver of large key orders. Patented key profiles are available for different segments such as locksmith dealer profiles, institutional locksmith profiles, locksmith distributor profiles and exclusive profiles such as for the government.

Abloy locksmith dealers are requested to purchase an Abloy key machine dedicated for cutting Protec keys, a service kit, key blanks and an opening order of Abloy products. Unique Abloy Protec dealer key blanks can be engraved with the dealer name and phone number. Abloy can also originate master key charts as needed.

For further information, contact Abloy USA, 6005 Commerce Drive, Irving, Texas 75063. 800-367-4598.