Wafer locks have been in use for over a century. Most wafer locks have wide tolerances built in to assure smooth operation. Those same wide factory tolerances often require at least a two-step depth difference between each key code to prevent key code interchanges. Under these conditions only 243 code numbers can be generated for most five-wafer, five-depth lock systems.

An office environment often requires several pieces of furniture to be keyed alike. This may require the removal and replacement of several lock plugs. Physical replacement of lock plugs or changing combinations plus replacing lost keys has always been an accepted procedure with wafer locking systems.

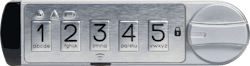

TriTeq Lock and Security has just introduced the MicroIQ pushbutton lock system which is designed to replace wafer locking systems currently used in most desk and cabinet locks. MicroIQ features a narrow one-inch wide keypad which easily replaces wafer cam locks in existing furniture and cabinets. TriTeq locks are distributed by ESP.

MicroIQ locks have been designed to easily retrofit existing locks on popular office furniture. This intelligent keypad lock will replace most wafer locks on Herman Miller, Haworth, Knoll, Steelcase, Hon, Wesco and Timberline furniture.

Installation consists of removing the existing wafer lock plug and leaving the original plug housing in place. Special spindles are designed to fit into the existing plug housing and connect directly to the original existing lock system. No mortising of the furniture is required. One small hole is required to secure the keypad to the door/drawer front. Instructions include a template to simplify placement of the small hole. The final step is to install the MicroIQ turn knob and secure it with an Allen head set screw.

Another version of the MicroIQ lock contains both the keypad and an attached camlock housing having the standard double-D shape. Cabinets and drawers which contain standard utility cam locks can be retrofitted with MicroIQ keypad locks by removing the complete existing cam lock housing and replacing with a MicroIQ. Straight or offset cams as required can be used to complete the installation. MicroIQ cam lock versions can be changed in the field for either vertical or horizontal double-D cutouts. MicroIQ cam locks can also be ordered with keypad numbers printed in vertical or horizontal order.

MicroIQ has two operating modes: Locker mode and Station mode. The Locker mode is designed for short term use such as if a visitor is given a code wich is temporarily usable. The Station mode is designed for long-term repeated lock use.

There are two levels of control for general MicroIQ lock operations: a Master code and a Supervisor code. The master code can be used like a master key and can be set to unlock each MicroIQ lock in a facility. A supervisor code is used when user codes are added. Master and Supervisor codes are set at the factory but can be easily changed as required in the field. User codes are at the lowest level and designed operate a small, coded-alike group of locks.

A user keyfob is also available which can operate a coded-alike group of locks instead of using the keypad. MicroIQ locks are equipped with an infrared receiver which can process infrared signals sent from the user keyfob. User keyfobs can also be paired together so one keyfob can operate additional MicroIQ locks. This simple procedure can be compared to master keying mechanical lock cylinders but without disassembly.

An additional accessory is their AutoTraq software. Audit trails of lock activity can be downloaded and displayed. Time of lock usage and key-fob owners are all recorded.

MicroIQ locks are a modern, economical answer for combining added security, simple operation and the electronic features now in demand by customers. For further information contact your local locksmith distributor or Hudson Lock, website http://www.hudsonlock.com.