Last month the Locksmith Ledger attended an annual event SHDA conference (Security Hardware Distributors Association) where manufacturers presented the products they would be introducing in the upcoming year. So we wanted to share some of the new things with our readers while also relating the new technologies to existing security techniques many of us have been practicing and using. You know, maybe put things into some sort of perspective.

We introduced the era of the smartlock in March; now we’re introducing the era of the smartlocksmith.

The concept is that locksmiths are the official purveyors of security locks hardware and keys, and we need to be smart enough to retain our title amid a jungle of competitors selling the wrong product to the wrong client, selling junky hardware and not injecting some professionalism and handholding into every transaction. So the smartlocksmiths are the guys who inventory the smartlocking products and are keeping the action moving at the lockshop.

It’s a cinch that you won’t find this smartlocking equipment on aisle 20 at the home center, and it is up to locksmiths to emphasize the relevance and value smartlocks are to security and safety, and to make it easy for the client to acquire these products.

Interchangeable Cores

Despite the adoption of electronics into security and access control, many mechanical lock products still are essential parts required to complete the total security solution. Interchangeable cores are a good example of smart locking solutions.

My introduction into interchangeable cores and controlled keyways was with retail banks where the ability to quickly rekey a branch at 5 p.m. Friday afternoon was a priority, as was the security of knowing that a key given to an employee would not be able to be copied.

The open window of opportunity for many was when the patent expired on the keyways and cylinders which were used on the majority of bank facility doors at that time.

The locks and cylinders became available from other vendors, but since relatively few facilities used interchangeable cores or patented keyways and each lock was uniquely combinated, the sunset of the patent did not usher in an era of lawlessness and financial ruin; at least not for bank depositors.

The open the window allowed new locksmiths to take over existing locking systems and for new restricted keyways to be sold to the banks to restore the former level of protection that patented keyways had previously provided.

There are many providers of patented keyways, interchangeable cores from which end users and locksmiths can choose from and an ever expanding market for high security products.

I think of the interchangeable core as the evolutionary missing link in locking technology, although the pin tumbler lock (Linus Yale 1848) might better bridge that transition. Today, the ability to instantly disable a door and change access authentication electronically is the single most significant feature we offered to win converts to electronic access control. Earlier, the interchangeable core offered similar benefits without electricity or wire.

Although mechanical keys are being used for typical door control, most system designers will include a single point of entry with mechanical lock using a restricted high security mechanical lock. Pert of the plan is to maintain total control over the keys that operate that door. A burglar and pick resistant/ restricted keyway on an interchangeable core represents the optimization of this plan.

A conventional cylinder is one that requires some breakdown of the lock in order to be removed. These are the most commonly used cylinders, sometimes called key-in-lever or key-in-knob. Manufacturer-specific to the lock and lock type, they cannot be exchanged for another in most cases. They can be keyed alike or master keyed so that you can use just one key for multiple locks if needed.

These are best suited for light commercial applications with a small number of users, such as retail stores and small offices, as well as residential applications that do not require frequent change of cylinders.

SFIC and LFIC

There are two types of interchangeable cores: Large size commonly called FSIC (full size interchangeable core) or LFIC (large format interchangeable core) and small size commonly called SFIC or small format interchangeable core.

The lock industry was able to agree upon a standard for Interchangeable cores. They are designed so that a particular format interchangeable core will work in any locking device designed for that format SFIC or LFIC.

The format of the cylinder is independent of the type of keyway in the core so the keyway is not limited to the brand of the lock, (for example Schlage or ASSA) as it is likely to be with a conventional lockset.

To determine if an interchangeable core is small format (SFIC) or full size (FSIC) look at the face of each core. The face of both cores looks like a "figure 8." With small format, both circles are concentric but with Full Size the bottom circle (or plug) is larger.

As you probably know, rekeying a conventional lock typically involves removing the knob if it is a key-in-knob, or the whole assembly if it is a deadbolt. Storefront doors are usually mortise cylinders which ostensibly can be more easily removed. I say ostensibly because I can recall several occasions where gnarly set screws and cross threaded cylinders and housings made the job much more difficult.

IC cylinders are designed to be replaced without disassembling the lock.

IC cylinders allow many levels of security upgrade potential including their ability to unify key systems on different brands of locks.

Interchangeable Core Cylinders - Interchangeable core (I/C, FSIC, LFIC, SFIC) cylinder offers maximum flexibility to the building owner. Whenever a key is lost or stolen, locks can be rekeyed quickly by non-locksmith personnel or the person responsible for building security.

A special CONTROL KEY is used to remove and install all cores in the system. The person responsible for building security will go to the door, remove the old core and install the new one with the CONTROL KEY. Security is regained in seconds!

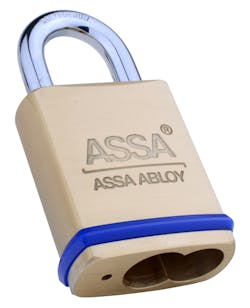

ASSA SFIC Padlocks

ASSA, Inc. introduces its SFIC padlocks. These padlocks can be used with any standard 6 & 7 pin SFIC Cores. These padlocks are covered under Buy America.

Features and Specifications:

- Double Ball Locking

- Suitable For Both SFIC 6 Pin Or 7 Pin Brass Cylinder

- Brass Body With Blue Bumper

- Clever-Shackle Systems, Patent Pending

- Super Tough Molybdenum Shackle

ASSA, Inc. is now offering LFIC Schlage® padlocks. These padlocks are covered under Buy America.

Features and Specifications:

- LFIC Schlage® Brass Interchangeable Core Padlocks w/o Core

- Brass body or chrome plated brass padlock available in 1-3/4"

- Padlock is supplied without cylinder and accepts Schlage® #23-030 series cylinder

- Bumper for protection

- Double ball bearing locking feature provides superior pull and pry resistance

- Clever shackle change design

- With Shackle Seal

- All products come non-key retaining Double Ball Locking

ASSA warrants its padlocks against defective workmanship or wear resulting from defects for one year

ASSA's SRB36 and SRB37 Resettable Brass Padlockis more reliable and impressive that the knock offs you’ll see on home center shelves. It is ideal xcellent for some but not all padlock applications.

It is a 4-Dial 10,000 Combination Resettable Brass Padlock with four wheels each numbered 0-9; combination can be 0000 thru 9999. Additional features include brass body and internal parts and weather seals for durability.

RX Web Access Control

RX Web is a web-based access control system which can control up to 16 doors, using a combination of ASSA ABLOY hard wired readers.

Rx Web does not require any software as this is stored within the RX Web controller. Administration is completed remotely using the web interface.

RX Web allows 1,000 users and eight separate reader groups with 15 time schedules.

RX Web works offline, permitting or denying access to users while also storing up to 20,000 events. Reports are available via the web interface.

RX Web control units will work seamlessly in the event of a communication failure. It will continue to permit or deny access to users as normal.

Control Unit RX 9101: Add up to a maximum of 4 wired doors and 15 Aperio® doors.

Control Unit RX9016: Add up to a maximum of 16 wired doors.

Pando mini: A card only mullion reader for exterior and interior doors. The reader can be configured for sector reading of MIFARE Classic, applications reading of MIFARE DESFire, iCLASS or SEOS. It is Hi-OTM enabled and available in a variety of colors.

Pando Secure: Card and keypad reader for exterior and interior doors. High security and Hi-OTM enabled.

ASSA Maximum+

Competitive with all patent restricted key systems and featuring one of the longest utility patent lives to 2030 makes Maximum+ Restricted one of today’s most valuable key systems. The added advantage of 9 cut depths provides exceptional master keying capability and expansion.

Maximum+ Restricted is a Low cost patented key control for internal doors where risk of physical attack is minimal. Maximum+ Restricted cylinders do not have side bars, side pins & side springs or drill resistance.

Maximum+ is a UL437 High Security system for exterior door and perimeter protection with patented keys to 2030.

For more information on the above ASSA Inc. options, contact your local locksmith distributor or visit www.assalock.com.

Medeco CLIQ

Medeco CLIQ is an Intelligent Key locking and access control solution, combining electronic and mechanical technologies. Managed via cloud-based software, Medeco CLIQ provides superior levels of controlled access and accountability. It installs quickly and easily without the need for wiring, power supply or changes to existing door hardware.

CLIQ Intelligent Key Features:

- Power is in the key

- Quick, low-cost battery replacement

- Up to 20,000 cycle battery life

- Water-resistant design

- Key holds up to 1,000 audit events

- Patented key control

- Provides mechanical and electronic security

- Color-coded cap for quick visual identification

- Available Prox/RFID cap for integration with HID compatible systems

- Available CLIQ Connect key for wireless updates via smartphone

CLIQ Cylinder Features:

- Quick, easy installation

- Simple retrofit for mechanical cylinders

- No power or wiring required

- No changes to existing door hardware

- Combines mechanical and electronic security

- Stores up to 750 audit events

- Rated for -20˚F to 122˚F

- Available in most standard finishes

- Wide variety of formats to fit most applications

K Series Cabinet Locks

K Series Cabinet Locks are flexible integrated cabinet lock solutions for extending access control to secure lockers, drawers or doors. The cabinet locks come standard with locked state monitoring, optional mechanical key override and over 150 lbs. of holding force.

K100 Series Wireless Cabinet Lock with Aperio® Technology

- Supports either HID® 125 kHz Prox or 13.56 MHz iCLASS® SE contactless credentials

- Battery powered by (2) AA lithium batteries

- Optional factory pre-paired lock and hub kits available

K200 Series Integrated Wiegand Cabinet Lock

- Featuring HID multiCLASS SE® contactless card technology

- Hard powered by 12-24VDC (+/-10%)

- Optional ElectroLynx™ interface cables available

Medeco XT

Medeco XT is a powerful Intelligent Key System that uses innovative technology to deliver a flexible, cost-effective solution for access control and accountability on every opening. The XT system installs quickly and easily without the need for wiring, a power supply, or changes to existing door hardware. Cloud-based hosting services ensure that a facility’s database is always secure, always accessible and always up-to-date.

For more information on Medeco products, visit www.medeco.com

Schlage’s CTE Single Door Controller

Schlage is enabling locksmiths to reach broader markets with new products from the expanded ENGAGE™ Portfolio

Allegion’s ENGAGE™ portfolio is the ideal package for locksmiths seeking to expand their connected solutions for customers, especially in multifamily and small commercial properties. The latest addition, the Schlage® CTE Single Door Controller and MT15-485 reader, works along with electrified exits, strikes or locks to extend electronic access control to perimeter openings.

Allegion’s™ recently introduced single door controller with multi-technology reader kit allows customers to manage all of their connected openings in one system, with one credential.

This allows perimeter and common area openings to be managed alongside the Schlage® Control™ smart deadbolts, NDE cylindrical and LE mortise wireless locks.

Features and benefits:

- Enables around the door solution with ENGAGE functionality for improved visibility and control

- Manage users and assign access privileges from virtually anywhere

- Built-in BLE and Wi-Fi

- Complete with Schlage MT11-485 or MT15-485 reader (required)

- No-Tour capable

- Flexible connectivity options: manage with ENGAGE web and mobile apps or with one of our Software Alliance Members

- Inputs: door position (DPS), request to exit (REX), request to enter (REN), remote release (REL)

- Outputs: lock relay , alarm relay, auxiliary (AUX) relay

- Input Power: 12 or 24 VDC or Power over Ethernet (PoE)

- Provides DC output power and dry control contacts

The Schlage Control™, LE or NDE wireless locks are ideal for interior applications.

All of these pair with Schlage’s smart credentials and can be controlled using the ENGAGE web and mobile apps—which were recently updated to improve the entire experience.

Users can easily manage access rights and gain greater control over their openings.

For more information

Mechanical High Security Q&A

Some additional perspective on mechanical locking comes from the Locksmith Ledger’s Gale Johnson, a third generation locksmith whose specialties include mechanical locks, interchangeable cores and masterkeying.

Who invented the interchangeable core and where were they originally used?

Frank Best invented the interchangeable core (IC) design and started the Best Lock Company in 1925. IC cores made it possible to remove a portion of the lock cylinder called the IC core, which contained the pins and springs, and install a different IC core cylinder without disassembly or removal of any other parts of the door lock. This procedure allowed an untrained person in authority to quickly change the key combination of a lock as needed. It is reported that popularity of the IC core system increased dramatically during World War II due to use at government military bases.

Are there any drawbacks to interchangeable cores?

IC core cylinder dimensions were made small enough to fit within an 1 1/4" mortise cylinder. Operating IC core plug diameters are approximately .435" and are now called small format IC core cylinders (SFIC). Standard plug diameters are approximately .500". Smaller SFIC diameters prevent most popular large key blanks from entering IC core cylinders. As a result, SFIC cylinders require special smaller-sized keyways and key blanks.

Is the core easier to remove (pick for removal) on some ICs than others? In other words does pick resistance qualities of a keyway also apply to the resistance to core removal?

Picking requires aligning every pin tumbler simultaneously at the shearline. Picking is simplified since standard cylinders have one shearline. IC core cylinders have two shearlines, one for the operating key and one for the control key. During the picking procedure it is difficult to determine which of the two IC core shearlines the pins have been raised to. In most cases picking will be raising pins to a combination of the two shearlines causing picking success to be more difficult compared to a standard lock cylinder.

Why are there large format and small format interchangeable cores?

Large format IC (LFIC) cores were invented to accept popular standard-sized key blanks. Different IC core retainer systems were invented allowing larger .500 diameter plugs to be used while eliminating the need for original Best plug within a plug designs. Popular manufacturers such as Schlage, Sargent and Yale each have their own IC core retainer design but keep the original Best idea of using a control key to remove and install LFIC cylinders.

How important is the patent?

The Best IC core patent is no longer applicable. This allows many lock companies to make SFIC lock cylinder which can accept original Best keyways. Many lock companies have invented high security features to protect their individual type of SFIC cylinders. Locksmiths now have a wide range of standard and high security IC core to choose from.

How was masterkeying developed?

Masterkeying has been performed for decades, but in my opinion it became formalized and documented by a lesser known individual who worked in the lock manufacturing industry. Hollis Devine worked for Schlage in the 1960s and developed a quadrant system (based on the power of 4) for masterkeying. Most commercial master key systems such as Schlage have 10 possible depths of cut (increments). Since the increments are close together, every other cut depth is used to keep change key cuts from causing interchanges when setting up a master key system. This leaves five usable cut choices for each space on the key. Since one cut depth is used for the master key cut, this results in four other choices available for use as change key cuts. Although Mr. Devine may not have been the first to invent this quadrant system, he is credited with developing charts to simplify the use of this quadrant master key system.

What are special function cylinders and where are they used?

Standard cylinders allow a key to be turned left or right as required to operate the lockset. Special function cylinders contain either special pinning or special parts which allow keys to perform different functions. An example might be a hotel function. The maid’s key will operate the lock as long as someone has not locked the door from the inside. A management key can override the locked hotel door and gain entrance in case of emergency.

Another example would be a lockout cylinder. A secondary set of pins is located at an angle to the normal vertical pins. A lockout key can be turned to the angle and the key is removed. The plug is no longer set at a vertical position and the tenant’s key can no longer be inserted. Lockout cylinders are often used to force tenants to pay their rent money before they can again have entrance to their apartment.

Another popular use of special cylinders is during new construction. A construction master is used until the building is completed. A regular master key is then inserted and turned. During the turning process the construction master pin is 'parked' in a slot and the cylinder automatically eliminates use of the construction master key blanks.

Tim O'Leary

Tim O'Leary is a security consultant, trainer and technician who has also been writing articles on all areas of locksmithing & physical security for many years.