HES 9000 SERIES: A Selection of Strikes for Most Installations

Life safety codes require the use of exit devices in specific situations, and most codes prohibit the use of any other lock or mechanism on the door that would prevent the use of the device or confuse the user.

The primary purpose of an exit device is to protect life safety by providing free egress to occupants of a building or room. These devices are designed for easy use, even in the dark.

The independent testing laboratories that test them require that they be relatively easy to operate, so they can be used by small children and physically impaired adults.

A rim type exit device is mounted on the surface of the push side of the door. If control of the door is required from the other side of the door, exterior trim is installed which communicates through the door to retract the exit device latch in the same way that pressing on the pushbar of the exit device would.

When electric locking and unlocking is required on a door equipped with a rim exit device, an electric strike is one possible solution. The electric strike can be installed in conjunction with a new installation or a retrofit situation.

Certain factors must be considered when selecting an electric strike for use with a rim exit device. One is whether the door is fire-rated, and the other is the distance from the head of the exit device to the door frame.

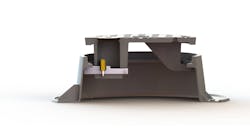

HES 9000 series electric rim strikes offer the installer a selection of strikes intended to meet most situations.

HES 9400

The HES 9400 electric strike is completely surface-mounted with a unique 1/2" slim-line form that is ideal for 1/2" throw rim exit devices in steel, aluminum or wood frames. The product is UL 1034 listed and exceeds ANSI/BHMA Grade 1 standards. Designed with a smooth new profile, the 9400 series features a cover that conceals the mounting screws and offers a sleek surface for superior looks and added strength.

Specifications:

UL1034 burglary-resistant rated

ANSI/BHMA, A156.31 Grade 1 (#E09731, #E09732, #E09373)

Patent 6,390,520 & patent pending

Frame application:

Metal

Wood

Electrical:

.45 Amps @ 12VDC continuous duty

.25 Amps @ 24VDC continuous duty

Standard Features:

- Completely surface mounted

- Decorative cover for sleek new look

- Stainless steel construction

- Tamper resistant

- Static strength 1,500 lbs.

- Dynamic strength 70 ft-lbs.

- Endurance 500,000 cycles

- Field selectable fail safe/fail secure

- Dual voltage 12 or 24 VDC

- Horizontal adjustment

- Non-handed

- Internally mounted solenoid

- Accommodates up to 1/2" Pullman latch

- Five year limited warranty

Optional Features

- LBM - Latchbolt monitor

- LBSM - Latchbolt strike monitor

HES 9500

With a new enhanced design, the 9500 series Genesis III™ continues to set the standard for fire-rated surface mounted electric strikes. All components are completely encased within its ¾” thick stainless steel housing, requiring no cuts to the jamb. Designed for use with rim exit devices, the 9500 series is field selectable to either fail secure or fail safe operation and can be operated with either 12 or 24 Volts DC.

Specifications:

UL 10C fire-rated, 3 hour (fail secure only)

CAN4-S104 (ULC-S104) fire door conformant

WHI fire door listed

UL1034, burglary-resistant listed

ANSI/BHMA A156.31, Grade 1 (#E09371, #E09372, #E09373)

NFPA-252 fire door conformant

ASTM-E152 fire door conformant

California Fire Marshall listed

NFPA 80-07 compliant

UBC-7-2-94, Uniform Building Code

Patent #6,390,520

Frame application:

Metal

Wood

Electrical:

.45 Amps @ 12VDC continuous duty

.25 Amps @ 24VDC continuous duty

Standard Features:

- Completely surface mounted

- Stainless steel construction

- Tamper resistant

- Static strength 1,500 lbs.

- Dynamic strength 70 ft-lbs.

- Endurance 500,000 cycles

- Field selectable fail safe/fail secure

- Dual voltage 12 or 24 VDC

- Horizontal adjustment

- Non-handed

- Internally mounted solenoid

- Accommodates up to 3/4" Pullman latch

- Five year limited warranty

Optional Features:

- LBM - Latchbolt monitor

- LBSM - Latchbolt strike monitor

HES 9600

With a new enhanced design, the 9600 series Genesis III™ continues to set the standard for surface mounted electric strikes. The 9600 accommodates rim exit devices in metal or wood jambs. The 9600 features an internally mounted solenoid and two stainless steel, independently-operating locking mechanisms. The 9600 is easy to install, with all components encased in the ¾" thick stainless steel housing, requiring no cuts to the jamb prior to installation.

Specifications:

UL listed to ANSI 250.13 Severe Windstorm

UL1034 burglary-resistant listed

ANSI/BHMA, A156.31 Grade 1 (#E09731, #E09732)

Patent # 6,390,520

Frame application:

Metal

Wood

Electrical:

.45 Amps @ 12VDC continuous duty

.25 Amps @ 24VDC continuous duty

Standard Features:

- Completely surface mounted

- Stainless steel construction

- Tamper resistant

- Static strength 1,500 lbs.

- Dynamic strength 70 ft-lbs.

- Endurance 1,000,000 cycles

- Field selectable fail safe/fail secure

- Dual voltage 12 or 24 VDC

- Horizontal adjustment

- Non-handed

- Internally mounted solenoid

- Accommodates up to 3/4" Pullman latch

- Five year limited warranty

Optional Features

- LBM - Latchbolt monitor

- LBSM - Latchbolt strike monitor

Perhaps you need a refresher on what all these specifications actually mean to your customers in the way of performance and safety.

Here are some brief explanations of these ratings and specifications thanks to Joshua T. Peabody, HES director of research & development.

UL 10C fire-rated, 3 hour (fail secure only)

Description: UL USA version - 3 hour positive pressure fire test of door assemblies and hardware that are built into a brick wall.

How Test Is Conducted: A wall assembly containing doors and hardware are sealed against a furnace that reaches 1900+ degree Fahrenheit over the course of a three-hour period. Water is then blasted at the doors and they must stay locked to pass test.

Relevancy: UL 10C fire rated products can be used in areas where building code requires a three-hour fire rating. A door with a three-hour fire protection rating is usually found in walls that separate buildings or that divide a large building into smaller fire areas. The wall rating is four hours.

UL1034, burglary-resistant listed

Description: These requirements apply to the construction, performance, and operation of burglary-resistant electric locking mechanisms and their related devices, such as control units, control switches, and power supplies, and the like used to secure and release doors.

How Test Is Conducted: Static, Dynamic and Endurance testing as follows:

a) Static strength rating of 500 pounds-force (2224 N), 1000 pounds-force (4448 N), or 1500 pounds-force (6673 N).

b) Dynamic strength rating of 33 foot-pounds-force (45 J), 50 foot-pounds-force (68 J), or 70 foot-pounds-force (95 J).

c) Endurance rating of 100,000 or 250,000 cycles.

Relevancy: These products can be used in areas where building code requires a certain grade for burglary-resistant openings.

ANSI/BHMA A156.31, Grade 1

Description: Establishes requirements for electric strikes and frame-mounted actuators, and includes definitions, general information and tests (required equipment and procedures). Illustrations, type numbers and descriptions are provided for mortised, semi-rim mounted and rim mounted devices.

How test is conducted: Static, Dynamic and Endurance testing as follows

a) Static strength rating of 500 pounds-force (2224 N), 1000 pounds-force (4448 N), or 1500 pounds-force (6673 N).

b) Dynamic strength rating of 33 foot-pounds-force (45 J), 50 foot-pounds-force (68 J), or 70 foot-pounds-force (95 J).

c) Endurance rating of 100,000, 300,000 or 500,000 cycles.

Relevancy: Implements "Grade" scale to static, dynamic & endurance rating.

NFPA-252 fire door conformant

Description: Part of UL10C rating.

ASTM-E152 fire door conformant

Description: Part of UL10C rating.

California Fire Marshall listed

Description: California recognized component for fire door applications

NFPA 80-07 compliant

Description: Regulates the installation and maintenance of assemblies and devices used to protect openings in wall, floors and ceilings against the spread of fire and smoke within, into, or out of buildings.

UBC-7-2-94, Uniform Building Code

Description: Part of UL10C rating.

ANSI 250.13 Severe Windstorm

Description: Laboratory windstorm simulation preformed on wood buck frame systems that contain door assemblies and hardware.

How Test Is Conducted: Static cycling, Dynamic hit and Endurance pressure cycling

a) 2x4 shot at door at predetermined speed.

b) Short burst static cycling determined by grade of test.

c) Endurance pressure cycling determined by grade of test.

Relevancy: These products can be used in areas where building code requires a certain grade for windstorm openings.

For more information, contact your local locksmith distributor or visit www.hesinnovations.com.

Tim O'Leary

Tim O'Leary is a security consultant, trainer and technician who has also been writing articles on all areas of locksmithing & physical security for many years.