The 1939 locksmith's tool box included far more than a file, chisel, hammer and screwdriver. See our 65th anniversary supplement, Pioneers of the Locksmith Industry, for additional stories on the history of this magazine and the locksmithing industry.

Even 60 years ago, there were some ingenious tools made to simplify many of the jobs done by locksmiths. One recurring theme concerning locksmiths' tools in the 1940s was that they were primarily mechanically-based. A few examples are shown here.

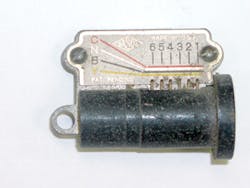

During the 1930s the H. Hoffman Company was both a distributor and a manufacturer of locksmith tools and supplies. One interesting tool was a lock decoder for Chrysler. Judging from the dates listed on the decoder, it was probably made in 1939 or 1940 just about the time when the first Locksmith Ledger was printed. Chrysler continued using the same lock designs from 1937 to 1948. Keyways were later changed but the same depth and spaces were used on most Chrysler locks until 1968.

HOFFMAN DECODER

The Hoffman decoder held a standard brass auto key in a special jaw. The top shoulder of the blank was trimmed away to allow a spring-actuated probe to fit along the blank. The probe was attached to a large dial indicator. As the blank was inserted into the car lock, the probe would hit the normal shoulder stop of the lock and the dial indicator would show which pin the tip of the key was touching.

The idea was to move the key blade near each pin and then turn the tool slightly so the pin tumbler would not be able to easily enter the top pin chamber. The tip of the key blank was then pressed against the tumbler. The tumbler was forced outward until it touched the cylinder wall. The dial indicator would then show a reading of the pin length and that tumbler space was decoded. After decoding all five spaces, an operating key could be quickly made without lock disassemby.

The tool worked best when a lock was a little worn so there was looseness which allowed the plug to turn slightly even though it was in a locked position. This tool has been discontinued for many years, but pin tumbler construction has not changed since the 1930s and the theory may still work.

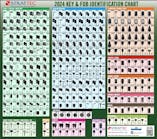

GM 6-CUT KEY CUTTER

Another automotive tool of note was a neat GM 6-cut key cutter. All you needed to cut keys was this tool, some key blanks and a medium-sized hammer.

GM used one a single-sided key blade shape from 1935 to 1966. There were six spaces and four depths. Briggs and Stratton lettered the tumblers C/N/B/Y. "C" was the highest cut and "Y" was the deepest cut. Original tumblers were color-coded: C=copper, N=nickel, B=black and Y=yellow (brass). This reporter correlated CNBY with "candy" to make the depths easier to remember.

Key codes were stamped somewhere on every GM auto lock cylinder. Chevrolet and Buick models had all locks keyed alike while Cadillac, Oldsmobile and Pontiac used Hex-shaped keys working the door and ignition and a round head key working glove and trunk locks.

Locksmiths could easily find the four-digit 8000-9499 code stamped on the lock or pawl and determine the key cuts from a code book.

The next thing was to cut a key and the Briggs & Stratton key cutter made quick work of doing that. An uncut key was first tightened into the jaw. The jaw section was spring-loaded. The operator would squeeze the jaw to release the spring pressure and then slide the height adjuster to a new depth. CNBY markings show up in a window on the machine to assure a correct setting.

Next, the spacer lever is moved to the space to be cut. The last step is to place the tool on a firm spot such as a workbench or even a curb or sidewalk if you were out on a service call. Hit the plunger on top with a light but firm tap and the key cut is made. Continue setting depth, spaces and hammering. A factory-looking original key can be cut in a matter of seconds.

People did not buy new cars every couple years during the 1940s and 1950s, so worn GM keys were a normal occurrence. All GM code cuts in the 8000-9499 series add up to an even number. Every GM key that came into our lock shop during those years was read by eye and then an original key was cut using the GM stamp machine. It was faster than duplicating and every customer left with a more exacting key than the one brought in for duplication.

For locksmiths who wanted to make sure they were cutting the correct key, Briggs & Stratton also made a key reader. The key was simply inserted into the housing. Cuts on the key pushed tumbler indicators into position and cut depths could be read by seeing which depth bar the tumblers aligned with. Any locksmith worth his pay could quickly figure out the four depths by eye so this tool got little usage in our shop.

It was a sad day in 1967 when GM brought out the 6-cut, 5 depth keys with new keyways. Our little GM key cutter could not cut the new "5" depth and it gradually got less usage. The Briggs & Stratton tool in these pictures is the same machine that this reporter used to make thousands of GM keys during the good old days of the 1960s!