Mortise cylinders have always been at the foundation of Medeco's product line. In fact, 10 Series mortise cylinders were the first to roll off the assembly line when Medeco opened its doors and started production in 1968. Although the overall mortise cylinder design has seen very little change over the years, the new Medeco3 design incorporates a new servicing procedure that is not present in the Medeco Original or Medeco Biaxial cylinder designs.

In this article we will look at servicing and pinning a Medeco3 mortise cylinder. We will also take a look back at some of the changes made to the Medeco mortise cylinder since its original design.

In the Beginning….

Originally, Medeco offered three lengths of mortise cylinders: 1", 1 1/8", and 1 ¼". Figures 1 and 2 show a 1970 cut-sheet from Medeco's original catalog on rim and mortise cylinders.

The original Medeco mortise cylinder design incorporated a solid, stainless steel pin chamber cover that had to be staked into place in order to contain the pins within the shell and plug. The solid pin chamber cover design was changed in 1977 to individually capped Allen set screws. This change helped to make the pinning and servicing of Medeco mortise cylinders more"locksmith friendly." This changed also made the cylinder more secure and less susceptible to sophisticated cylinder attacks such as the comb attack.

The face of Medeco mortise cylinders has also seen changes over its 35-year life. The name Medeco went from all uppercase letters to lowercase letters and now includes the UL product series designation for that type of cylinder. A logo that identifies the cylinder technology being used within the cylinder has also been added.

With the introduction of Medeco Biaxial in 1986, the only major change to the mortise cylinder design was the location of the locator tab slots located on the top of the shell and plug. In Medeco Biaxial product, the locator tab slots point to the right of the shell (looking down at the top of the cylinder) instead of toward the back of the shell as in original product.

Medeco3 Mortise Cylinders

Medeco3 mortise cylinders incorporate the same level of drill protection offered by Medeco Original and Medeco Biaxial mortise cylinders. This includes two hardened steel crescents located in the face of the shell at the 12 o'clock and 3 o'clock positions, hardened steel rods in the plug face at the 12 o'clock and 3 o'clock position and a hardened steel ball bearing located in the face of the sidebar.

The Medeco3 cylinder design is different than its predecessor in the fact that it includes a third locking point in the form of a slider mechanism. This slider mechanism blocks the sidebar from making contact with the bottom pins until a key with the proper side bitting is inserted into the cylinder.

Medeco3 mortise cylinders meet and exceed ANSI/BHMA A156.5-2001, Auxiliary Locks & Associated Products Grade 1 Listing. Medeco3 mortise cylinders also meet ANSI/BHMA A156.30-2003, High Security Cylinders standards (M1AAAM).

Disassembly

The Medeco3 mortise cylinder can quickly and easily be disassembled in the field. However, disassembly is not required when re-keying since the pins can be loaded through the top of the cylinder. These procedures should only be used for cylinder cleaning and component servicing (wear/damage/slider replacement).

Servicing Tools Required:

· Medeco screwdriver or Phillips head screwdriver

· Small flat blade screwdriver

· Cut key, key blank, or probe (pick)

· Tweezers

Step 1. Remove Cam Screws, Cam Washer, and Cam. Medeco mortise cylinders are equipped with a changeable cam that can be changed quickly and easily in the field to meet the requirements of the application. Before the plug can be removed, the cam screws, the cam washer, and the cam must be removed from the back of the cylinder.

Step 2. Remove Plug. In order to remove the plug, you will need a working key, a key blank, or a probe. If cut keys or key blanks are used, they must contain the proper side bitting for the slider installed in the cylinder. Before the plug can turn, the slider mechanism must be pushed into a position to align its blocking tabs with the gates in the sidebar. Insert your key into the cylinder and turn it 45 degrees. Once the plug is turned, push the plug from the back of the cylinder. You may want to hold your finger over the slider and the sidebar while pulling the plug out. Pull the plug out slowly to prevent losing any of the components.

If a cut key or a key blank is not available, the slider can be pushed inward with a pick or a probe while apply turning force to the plug. This will allow the plug to rotate so that it can be removed from the shell.

Step 3. Remove the Hardened Steel Crescent Inserts. After the plug has been removed, the hardened steel crescent inserts can be removed from the shell. Take the shell, holding it at an angle with the face down, and lightly tap it on a hard surface. The hardened steel crescent inserts will fall out of the shell.

Step 4. Remove the Slider Mechanism from the Plug. The slider mechanism is located on the bottom of the plug on the right-hand side. Taking a small flat blade screwdriver, gently pry up on the slider mechanism to release it from the pocket and to remove it from the plug. You will also need to remove the slider spring.

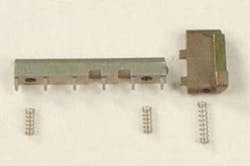

Step 5. Remove Sidebar from Plug. After the slider mechanism is removed from the plug, the sidebar is ready to come out. Remove the sidebar by turning the plug on its side and tapping gently on table or bench top. The sidebar springs will also need to be removed. The sidebar springs may still be in the sidebar or they may be in the sidebar pocket.

Note that the slider spring and the sidebar springs are of different sizes and are not interchangeable. Also note the location of the springs in the sidebar and the slider. (Figure 15)

The disassembly of the Medeco3 mortise cylinder is complete and the components are now ready to be serviced, cleaned or replaced. Figure 16 shows an exploded view of a disassembly Medeco3 mortise cylinder.

ASSEMBLY OF Medeco3 BIAXIAL Mortise Cylinder

Step 1. Insert Hardened Steel Crescents. (Figures 17 & 18) Place the shell on its side so that you can look down at the slot cut under the face of the shell. Using tweezers, insert the two hardened steel crescents into their respective slots.

Install the crescents with the concave side pointing to the hole for the plug. The convex side of the crescent should be pointing toward the shell. You may notice that the crescent is beveled on one side and flat on the other. This makes no difference during installation. The crescent can be installed with the bevel pointing toward the face or with the flat side toward the face. After the hardened steel crescents have been inserted, position the shell upright to keep the crescents from falling out.

Step 2. Place Slider Spring in Slider. Place the slider spring into the hole locator on the slider (longer spring).

There are two methods to installing the slider in the plug. Both methods are listed below:

Step 3A: Insert Slider into Plug – Spring End First. Insert the slider into the pocket on the bottom of the plug, spring end first. There is a ledge along the back side of the pocket for the slider spring to rest on. Make sure that the spring is not sitting down below the ledge.Step 3B. Insert Slider into Plug – Spring Resting on Plug. Install the slider into the plug by inserting the non-spring side of the slider first with the spring resting on the plug. Once the non-spring side is seating in the pocket, the spring can be compressed and lowered into its position in the slider pocket. The slider spring should rest on a ledge along the back side of the pocket. Make sure that the spring is not sitting down below the ledge.

Step 4. Test Slider. After the slider mechanism is installed in the slider pocket, test the slider to make sure it has the proper amount of spring tension by taking a small flat blade screwdriver and pushing the slider mechanism toward the back of the plug. The slider should seat flush with the back side of the pocket. If the slider is not moving smoothly or is not seating flush with the back of the pocket, complete Step 4 of the disassembly instructions and then reinstall the slider and slider springs (Step 3 in reassembly instructions).

Step 5. Install the Sidebar. (Figure 26) After the slider mechanism has been installed, we can install the sidebar. Place the sidebar springs (shorter springs) in the holes located at each end of the sidebar. Place your finger over the slider mechanism in the plug to keep it from falling out. While holding the sidebar horizontally, with the sidebar springs pointing up, place the plug over the top of the sidebar. The plug will have to be rotated so that the sidebar pocket is pointing down. Note that the hardened steel ball bearing in the face of the sidebar should be positioned toward the face of the plug. The sidebar will not go into the plug all the way until a key is inserted.

Step 6. Insert Key into Plug. (Figure 27 & 28) Before we can insert the plug back into the shell, a key will need to be inserted into the plug. With no key in the plug, the blocking tabs of the slider are blocking the sidebar from being pushed in. In this state, the plug will not be able to be inserted.

While inserting the key, hold your finger over the slider to prevent it from popping out. After the key is fully inserted into the plug, push in on the sidebar. If the sidebar does not push in, you may be using a key with the wrong side bitting, you may have installed the wrong slider, or the sidebar springs may have tipped.

Step 7. Insert the Plug into the Shell. In order to insert the plug into the shell, push the key in all the way while also pushing in on the sidebar. This process is made easier by standing the shell upright while inserting the plug from the top rather than the side.

Step 8. Install Cam, Cam Washer, and Cam Screws. Once the plug has been fully inserted into the plug, the cam, the cam washer and the cam screws can be reinstalled. The back of the cam should be flush with the back of the shell and the cam washer hole should be in line with the keyway (not covering it).

On five-pin Medeco3 mortise cylinders, the cam screw located on the left side (looking from the back of the cylinder) will be shorter than the one on the right. The left cam screw is shorter so that it will not interfere with the slider mechanism. The shorter cam screw should be installed in the 7 o'clock position on the cam washer.

The Medeco3 mortise cylinder is now completely reassembled and is ready to be pinned. Part numbers for the cam washer and the cam screws are shown in Figures 31, 32, & 33.

PINNING MEDECO3 MORTISE

CYLINDERS

Medeco3 mortise cylinders are pinned in much of the same manner as standard pin tumbler cylinders; however, they are top-loaded and do not require a plug follower. Medeco3 mortise cylinders are pinned from bow to tip (cylinder face to cam).

Keep the following information in mind when pinning Medeco3 mortise cylinders:

· Mushroom top pins should be inserted with the cap pointing down toward the bottom pin.

· If possible, two mushroom top pins should be used in each cylinder. The mushroom pins provide additional pick resistance.

· Two hardened steel top pins should be used in each cylinder. These pins provide additional drill resistance.

Pinning Tools Required:

· Pinning kit – K-5001 (Large Pinning Kit), K-5005 (Small Pinning Kit)

· Cylinder holding fixture (optional) – CP-282451

· Medeco screwdriver or 5/64" Allen wrench

· Key decoder – 94-0032

· Medeco KeyLube 2.0 – PX-KYLUB2-03

· Tweezers (optional)

Step 1. Determine the pinning of the cylinder. This can be accomplished by decoding a key, decoding a blind code, or referencing the pinning from a bitting list.

Step 2. Load the cylinder into the holding fixture.

Step 3. Secure the cylinder in the holding fixture by tightening the cylinder set screw located on the side of the holding fixture.

Step 4. Insert the key that the cylinder is to be pinned to. You will use this key to test the cylinder pinning as each pin chamber is loaded.

Step 5. Select the proper bottom pin from your keying chart or bitting list and load it into the cylinder. (Figure 37) Place the pin over the pin chamber with the locator tab on the pin directly over the locator tab slot in the pin chamber hole. Do not force the pin into the pin chamber. If the locator tab is not aligned with the locator tab slot, rotate the pin until both are aligned. Test the key after each bottom pin is inserted.

If the key does not rotate the plug, the pin may not be fully seated on the cut of the key. Lightly press down on the pin to seat it on the key.

CAUTION: Only push down on the pin if you are sure that the locator tab on the pin is aligned with the locator tab slot in the pin chamber hole.

If the key still does not turn, it is likely that the improper pin was used. Extract the pin and use the correct one. Check your pinning kit and the pinning information.

Step 6. Load the corresponding top pin. The required top pin number will match the corresponding bottom pin number. This is necessary to maintain a consistent pin stack height within the pin chamber. An example of this would be a number 5 length bottom pin with a number 5 driver on top.

If you are master pinning this cylinder, load the master pins in the cylinder before the top pins. In a master keyed situation, the top pin number will be a number that equals the total of the bottom pin and the master wafer added together.

If you are using a mushroom driver, make sure the cap is pointing down toward the bottom pin.

Step 7. After the top pin is loaded, test the key to ensure that it operates. If the cylinder is master pinned, test all keys that were designed to operate this cylinder.

If the key works, repeat steps 5 – 7 for the remaining pin chambers until all pin chambers are loaded with the necessary bottom and top pins. If the key does not work, recheck the pins used in that pin chamber.

Step 8. Once all of the pin chambers have been loaded with the proper bottom and top pins and the cylinder has been tested with a key, slowly remove the key. Load the tumbler springs.

Step 9. Once the tumbler springs have been loaded, you can begin to cap each pin chamber. A 5/64" Allen wrench is required to secure the Allen set screws in each pin chamber. The set screws should be lightly snug and be deep enough to clear the mortise cylinder threads. If the set screws are over tightened, they may be difficult to remove. This may also cause too much pressure on the pin stack and the cylinder will be difficult to operate. Once the Allen set screws are secured into place, the cylinder can be removed from the holding fixture. The cylinder is now ready for installation. It is not necessary to use Lok-tite on the set screws.

Today, Medeco mortise cylinders are available in lengths from 1" to 8" and in a wide assortment of finishes. Medeco has also expanded its mortise cylinder line to include many special function/application cylinders. A variety of cams, spacer rings, and collars are also available to meet the requirements of your application. For more information on Medeco mortise cylinders, please contact Medeco Technical Services or log onto our web-site at www.medeco.com.