I’ve known Larry & Cliff Shafer, owners of CLC Locksmith, for quite some time but only met Larry’s son Tommy in the course of the past year. I didn’t realize he was not even 17 yet and thought that as a part of our 30 under 30 series, I’d speak with both father and son together. When I first arrived at their shop after 5 p.m., Larry was on his way back from a job and his brother Cliff was kind enough to fill in. The following is how the conversations went.

Cliff, what does CLC actually stand for?

Clarence, Larry and Cliff. Clarence was dad, and since he’s passed, I’ve taken liberties and now it’s Cliff, Larry and Clarence.

Tom, how long have you been hanging around here in the shop?

Since I was very young, whether I was working or just hanging out with my dad and the guys. I always liked being here, cutting keys and other stuff. I was too young to remember when I cut my first key.

Do you remember being here when your grandfather was here?

CS: Actually Tommy would have been too young to remember that. Our dad started the business in 1972 when Larry and I were in high school. Larry came to work here out of high school and when it got busy, my dad asked if I wanted to come to work. I was in college as a communications major and decided this would be the better choice. My dad did not give us the business; he sold it to us.

So when did you begin to realize the full breadth of what goes on in a lock shop and how cool it is to be opening and repairing people’s locks for them?

TS: It was almost a year ago when I started working here every day after school. That’s when I really started learning a lot more.

Whose idea was it for you to come into the shop?

My dad knew I would if he asked me to and I wanted to take advantage of the opportunity. I started coming in a couple of times a week and eventually I was coming in every day.

Do you see locksmithing as a way to earn a living and support yourself in the future?

Yes I do. There’s a lot to learn but I’m doing it slowly and getting the hang of it.

What have been some of your first responsibilities as a paid employee?

TS: I’ve been rekeying locks and learning something new every day.

CS: Just like most people coming in and starting at the bottom, he’s started out doing things like cleaning the key machines, sweeping the floor and taking out the garbage. That’s all part of it. You don’t come in here at the top, and you work your way up from the bottom.

Do you think you’re treated any differently because you’re the son and the nephew of the owners?

TS: No, I’m treated the same way; they all mess around with me. I get treated the same as everyone else.

At this point of the interview Larry Shafer, Tommy’s father, has returned and will participate in the rest of the interview. Cliff, Tommy’s uncle, says good bye.

Did you love coming to the shop when you were a little kid?

TS: Yeah, I did. I remember when I was around 7 years old and playing with the box of keys in the back. I tried to help but I was pretty young.

Larry, were you thinking back then that Tommy might be working here with you one day?

LS: My attitude was always that if my kids wanted to, that was fine and if they didn’t, it was totally understandable. The opportunity was always here for them.

TS: It was always in my mind and I did always wonder about it.

LS: He’d come in to say hi sometimes and being the slave driver that I am, I’d put him to work.

Were you thinking it would be to Tommy’s benefit for him to work here or for your benefit to have him here?

It would be to his benefit if it were something he wanted to do.

Were you always good with your hands? Do you think people can be taught to work with their hands or are they born with it?

LS: He’s pretty mechanically inclined. I think they either can or can’t from the start but there’s a level of patience that’s required to be good at it. Patience is important for me to this day and that’s the part that I think is hard to learn, either you have patience or you don’t.

Larry, what are some of the biggest changes you’ve seen since you started with your dad back in 1976?

Well, electronic security was virtually nonexistent back then aside from some government locations.

Was it easy for you to transition into the world of electronics?

LS: No.It’s a learning process and something that’s changing constantly. I don’t think anyone would say they know it all.

Tommy, when you think of locksmithing, do you automatically consider electronics as a part of it?

TS: I do. For as far back as I can remember, electronics have been a part of it. I think of both the mechanical and electronics when I think of what I need to learn.

Larry, how was it different when you think back to the 1970s?

LS: Back then it was mechanical only. When it came to automotive, the only thing electronic was maybe an aftermarket alarm that someone had; no transponders, no Vats systems. Things have changed quite a bit. I remember when GM changed from the spring loaded retainer to using a screw to hold the cylinder in and that was a big deal. I knew locksmiths who wanted to get out of the business because they couldn’t slap out the cylinders any more. I was fine since I never slapped them out to begin with.

Tommy, did you ever go with me on lockouts when you were little?

TS: I think I went on a couple. I remember us opening cars for a couple of my friends.

LS: His mom would drop him off when she had to and he had no choice.

Did you like fooling around with picks and locks when you were little?

LS: We had an American padlock lying around here that no one was able to pick and Tommy did it.

TS: My older brother Ryan and I would have contests when he was here. We’d grab locks off the displays and time each other and there were a few things I was able to pick open when I was just hanging around and not working here yet.

LS: Normally you wouldn’t even try to pick and would sell another one. The customer who left it had a bunch more with the same key and we had to pick this and make a key that would work all the others. None of the other guys here could get it and I jokingly asked Tom to open it and to my amazement he got it after 5 or 10 minutes.

Did you have any preconceived notions coming in? What has been different than you thought it would be?

TS: Things looked easier than they actually are, whether it’s dealing with people over the counter or some of the work we do behind the counter. I’ve been learning a lot about communicating with customers, being more aware of the way I talk to them.

I know that a major issue in our industry is knowing what questions to ask. Do you think that’s important to learn?

LS: I agree 100 percent. Some of the guys who have been here for awhile still don’t ask the right questions. It’s important so we don’t go out to do a job and find out we’re not prepared. It takes a while to do that right.

What do you ask when someone calls and tells you they want their locks changed?

TS: I ask if we’re going out or are they bringing the locks here.

LS: He knows some of the right questions but it’s hard until you’ve gone out and done some of the work, which I’ll be doing with him soon.

Larry, what’s the difference between working with your son and another apprentice? Are you gentler or tougher on him?

I try to treat him like anyone else. He doesn’t get any breaks from me. I’m on the road most of the time and don’t always know what goes on between him and the other guys.

TS: I’d rather be treated the same as the others. I don’t want it to seem like I’m getting better treatment because there would be some resentment by the others.

What do you think you’d be interested in doing if you hadn’t grown up in a locksmith environment?

TS: Automotive, in school a big thing is the automotive shop. A couple of times I’ve had to call here to solve problems on cars, like when the security light comes on.

From what you’ve seen so far, what aspects of locksmithing you would like to focus on given the choice?

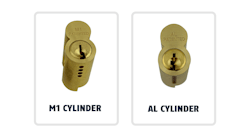

I like working on everything and like picking open and keying cylinders; I’ll do anything. I’ve done some masterkeying and work on IC cores too. I look forward to learning something new every time I come to work here.

Aside from the hands on lock work, do you see the business as something that you might own or run one day?

TS: Yeah, I pay attention to the things my dad and Uncle do at the end of the day with the register and credit cards. I like learning the business aspect as well.

Where do you see locksmithing going in the future?

TS: It’s too unpredictable anymore with electronics being the biggest thing. Electronics have been a big part of it since I got here and I see that aspect of locksmithing just taking up more and more of what we do.

What are you amazed by so far?

TS: Biometrics; that’s the kind of stuff I see really taking off. Now even Kwikset is using it and it’ll be used in residential as well as commercial applications. I won’t be amazed if in ten years, most front doors had something biometric on them. Fingerprints can’t be duplicated like a key so I do see it really taking off.

Larry, do you remember what you thought the future in locksmithing would be like when you started out?

LS: I grew up doing this with my father before Cliff even got involved and cutting keys was a big thing just like it is today. I ended up with the old school way of doing things and securing things and it’s progressed a lot since then. I try to teach Tommy the way I was taught and to avoid shortcuts. He hasn’t been taught electronics yet and I teach him pretty much the same way I learned 30 years ago. There’s good and bad shortcuts. Obviously you want to get things done quickly but you don’t want to wind up compromising someone’s security in any case.

TS: It takes a little longer to do it right but you avoid having a problem later so it’s worth it.

Do you remember the need for security being as important 30 years ago as it is now?

LS: I think it was. There were as many residential break-ins as there is today, maybe even more back then. I don’t think the need has changed; only the way we secure things has evolved. Now you could time people in and out where in the past you had a key and you got in when you wanted. I haven’t seen an increase or decrease in the actual need for security.

Would you recommend this business to young people today?

LS: Honestly? I think there’s easier ways to make a living, no doubt about that. If you’re mechanically inclined and you like problem solving then this is still a pretty good option. Can you make more money doing other things? Yes, without a doubt.

Can anyone who’s good with their hands do this for a living? What else does it take?

TS: There’s a lot to learn and there’s a lot to remember.

LS: I would say 50/50; you need mechanical ability and you need to think out things like master key systems. You need to use your brain a lot; you can’t just be good at turning a screw.

It sounds like locksmiths should be highly compensated when you consider the abilities needed to be good at it.

LS: I agree. It should pay better than it does today.

Do you see locksmithing continuing as the small business, Mom & Pop type business?

No. I see it being less and less family oriented; I see the family business going away. The way things are now, you can call from here in New Jersey and someone is answering the phone in New York at a dispatch center. And then there are the scams we have around here; it’s becoming a big business for some and not all for the better.

Do you enjoy being here and tending to the phone book ads, etc.

LS: No I don’t. I enjoy the hands on work and would rather be on the road doing things than sitting in the shop dictating what needs to be done.

Tommy, do you enjoy being in the shop?

TS: Yes, but that’s the only part of the business I see right now. I don’t have anything else to compare it to.

Steve Kaufman

Steve Kaufman has worked for distributors in the locksmith industry since 1993 and worked as a full-time locksmith from 1978 through the 1980s. Kaufman is the sales manager for IDN Hardware out of its Philadelphia location.